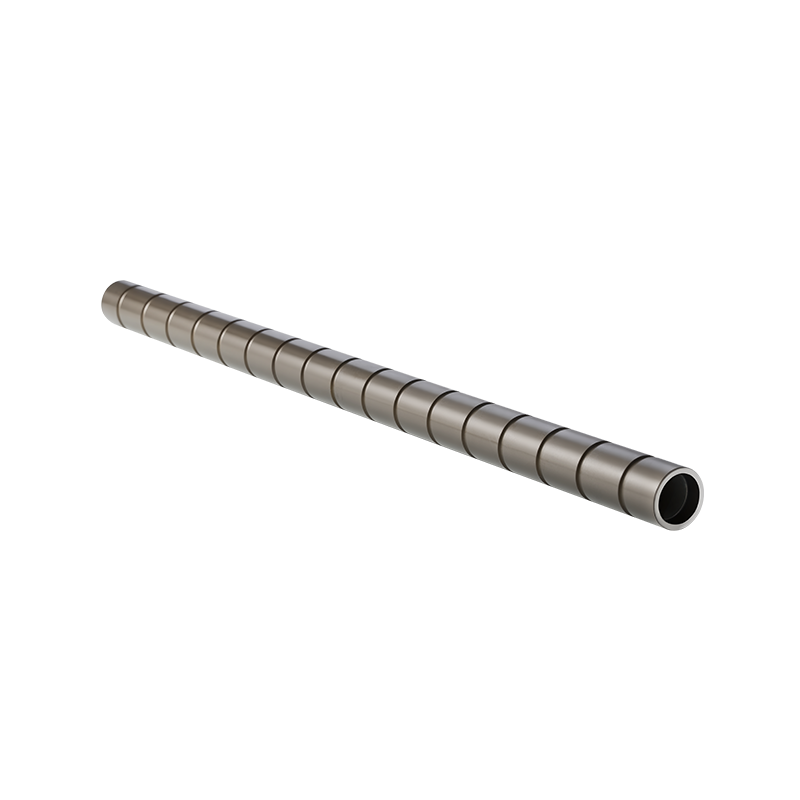

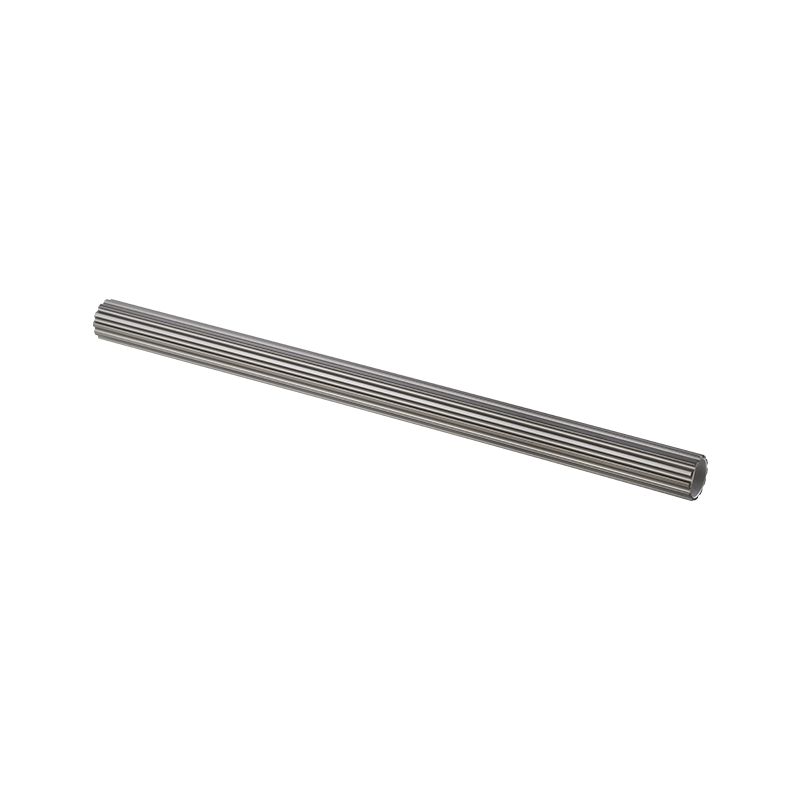

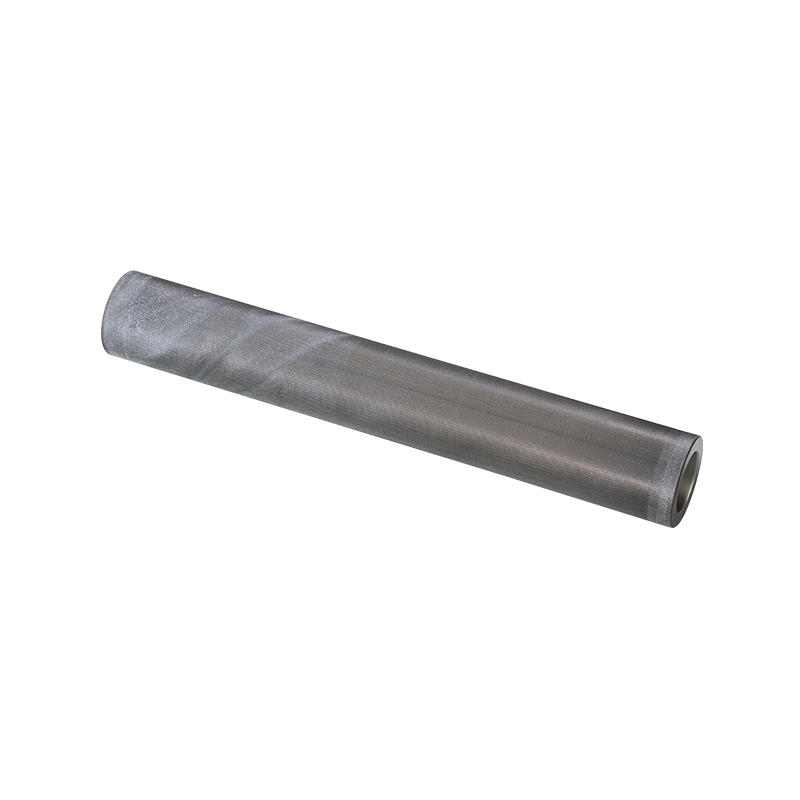

The roller surface is meticulously machined using precision equipment and specialized tooling to achieve exceptional smoothness and concentricity accuracy of up to 0.02 mm. Dynamic balancing ensures stable rotation with minimal vibration, while high-quality imported bearings ensure smooth and flexible movement.

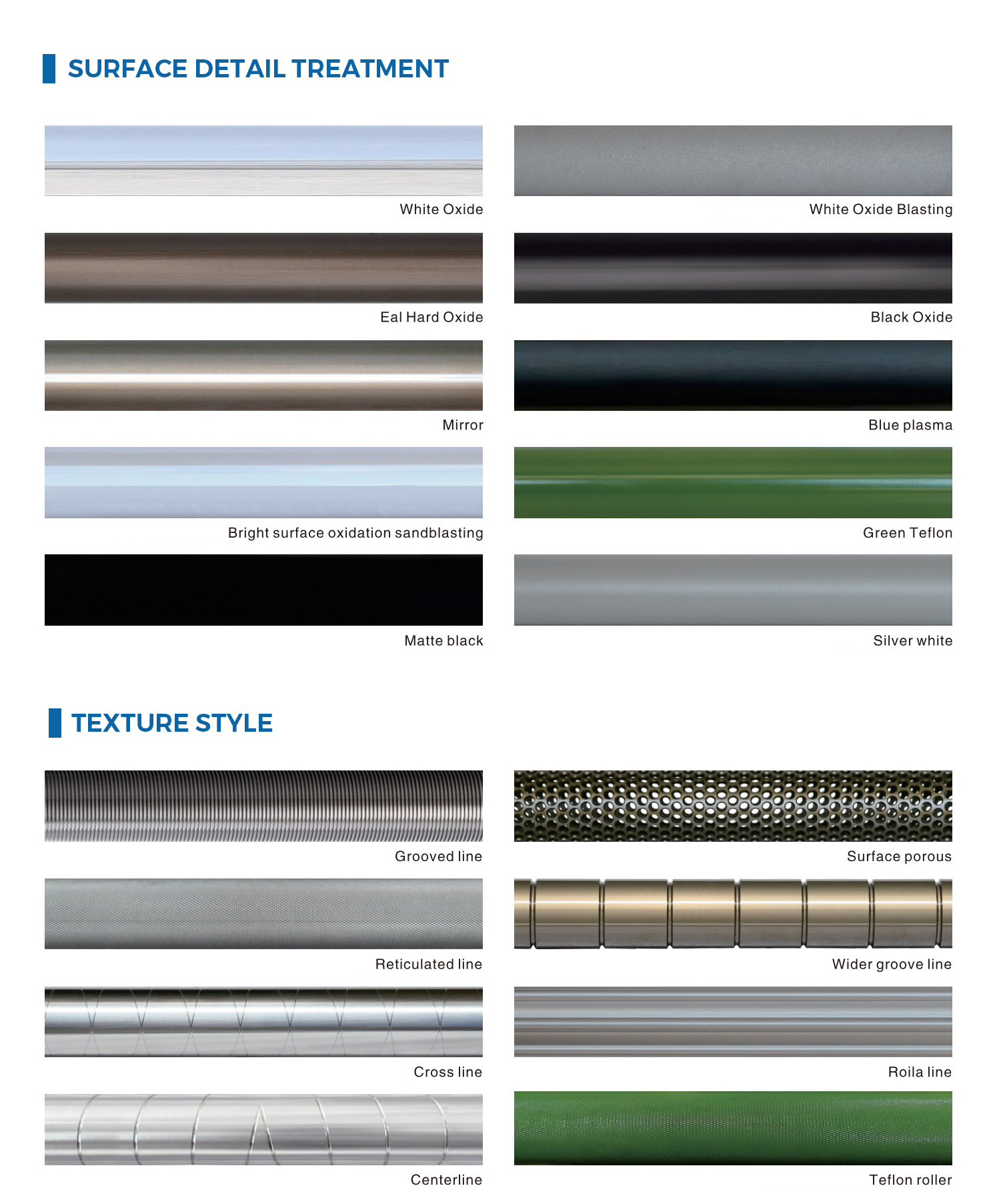

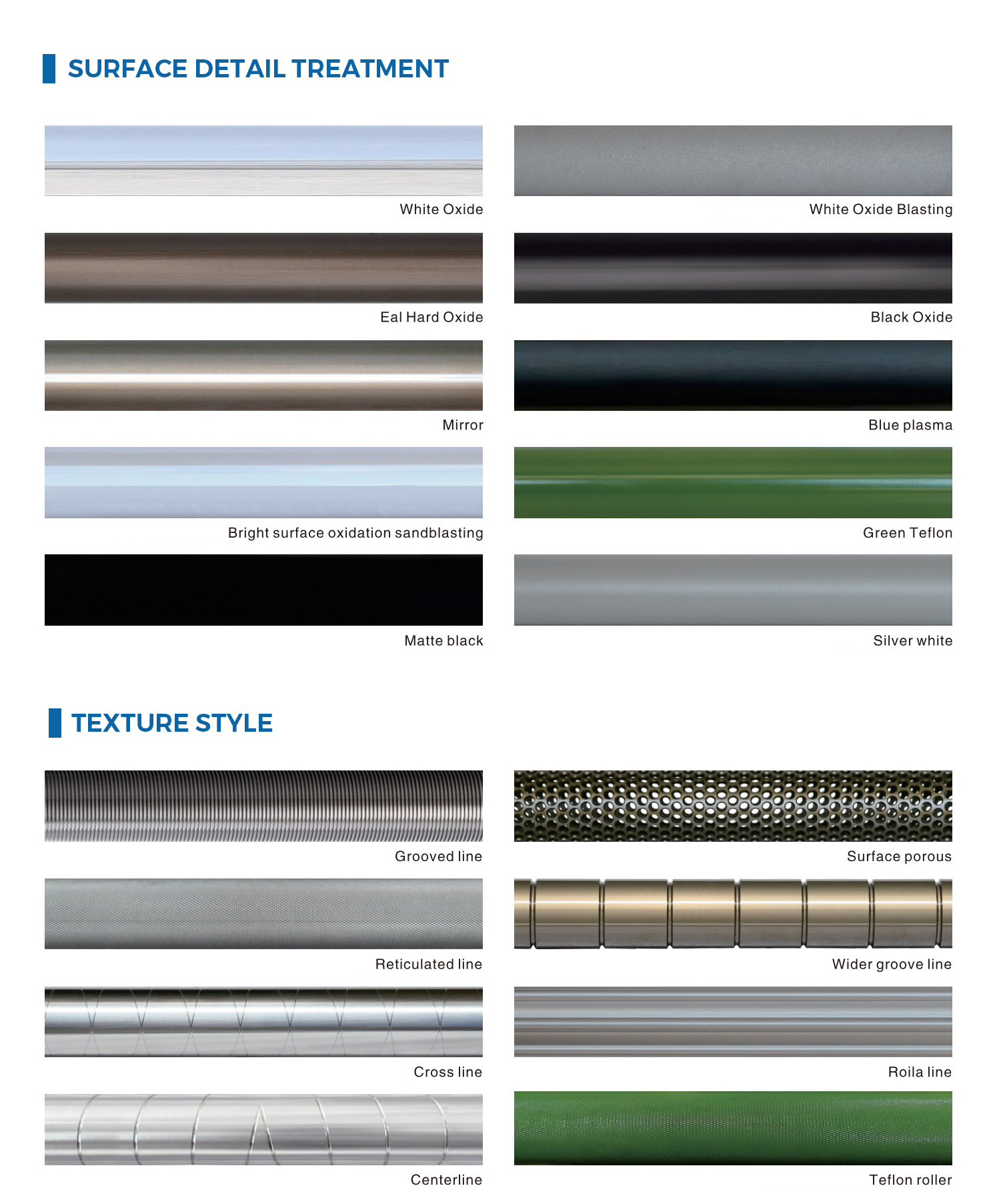

The surface is treated with a white anodized finish with a moderate hardness (HV300) for a bright, corrosion-resistant finish while maintaining lightweight and rust-resistant properties. The smooth, non-marked surface reduces running resistance, making it ideal for handling thin films and low-tension materials. Further surface treatments such as sandblasting, knurling, or hard anodizing are available to meet specific industry requirements.

This aluminum guide roller offers high precision, good wear resistance, and a long service life. It is widely used in packaging machinery, bag making machines, printing equipment, coating and laminating machines, slitting lines, papermaking machinery, and textile processing equipment. It is an efficient, durable and cost-effective choice for modern industrial applications.

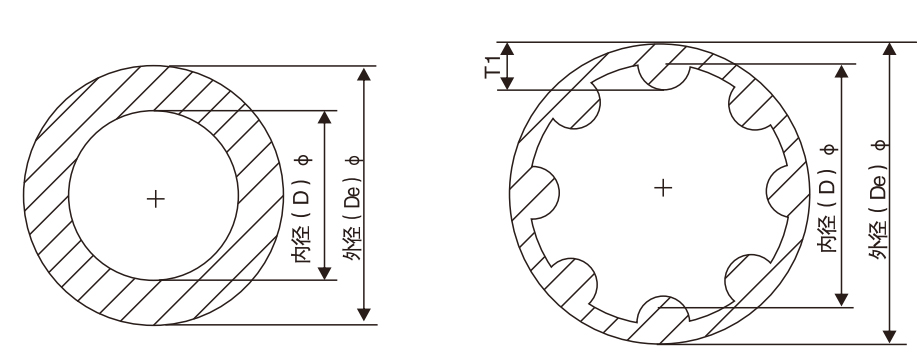

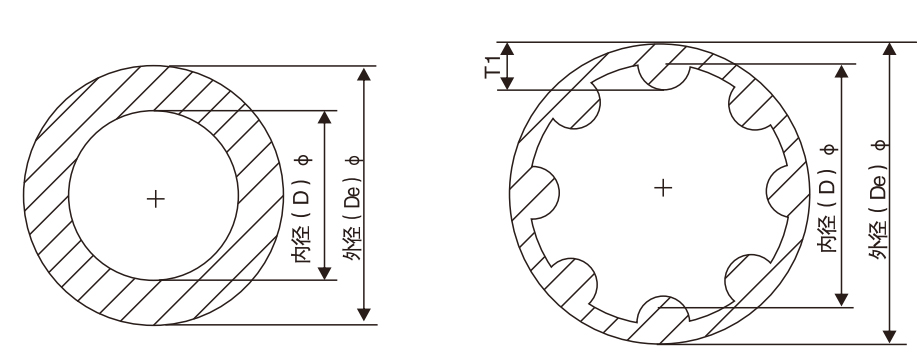

| (De)Φ |

(D)Φ |

THICKNESS |

T1 |

T2,T3 |

Number of stiffeners |

| Φ22 |

Φ16 |

3 |

|

◉ |

|

| Φ25 |

Φ20 |

2.5 |

|

◉ |

|

| Φ31 |

Φ23 |

4 |

|

◉ |

|

| Φ31 |

Φ25 |

3 |

|

◉ |

|

| Φ34 |

Φ26 |

4 |

|

◉ |

|

| Φ38 |

Φ30 |

4 |

|

◉ |

|

| Φ40 |

Φ30 |

5 |

|

◉ |

|

| Φ43 |

Φ33 |

5 |

|

▲ |

|

| Φ50 |

Φ40 |

5 |

|

▲ |

|

| Φ55 |

Φ45 |

5 |

|

▲ |

|

| Φ57 |

Φ50 |

3.5 |

|

▲ |

|

| Φ59 |

Φ50 |

4.5 |

|

▲ |

|

| Φ60 |

Φ50 |

5 |

10 |

▲ |

6 |

| Φ70 |

Φ61 |

4.5 |

10 |

▲ |

6 |

| Φ75 |

Φ66 |

4.5 |

10 |

▲ |

6 |

| Φ81 |

Φ71 |

5 |

10 |

▲ |

8 |

| Φ91 |

Φ81 |

5 |

10 |

▲ |

8 |

| Φ101 |

Φ91 |

5 |

11 |

▲ |

8 |

| Φ101 |

Φ87 |

7 |

11 |

▲ |

8 |

| Φ111 |

Φ99 |

6 |

12 |

▲ |

8 |

| Φ121 |

Φ109 |

6 |

12 |

▲ |

9 |

| Φ131 |

Φ118 |

6.5 |

13 |

▲ |

9 |

| Φ141 |

Φ128 |

6.5 |

13 |

▲ |

9 |

| Φ151 |

Φ137 |

7 |

14 |

▲ |

9 |

| Φ201 |

Φ179 |

11 |

|

|

|

| Φ300 |

Φ270 |

15 |

|

|

|

Español

Español Deutsch

Deutsch

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More