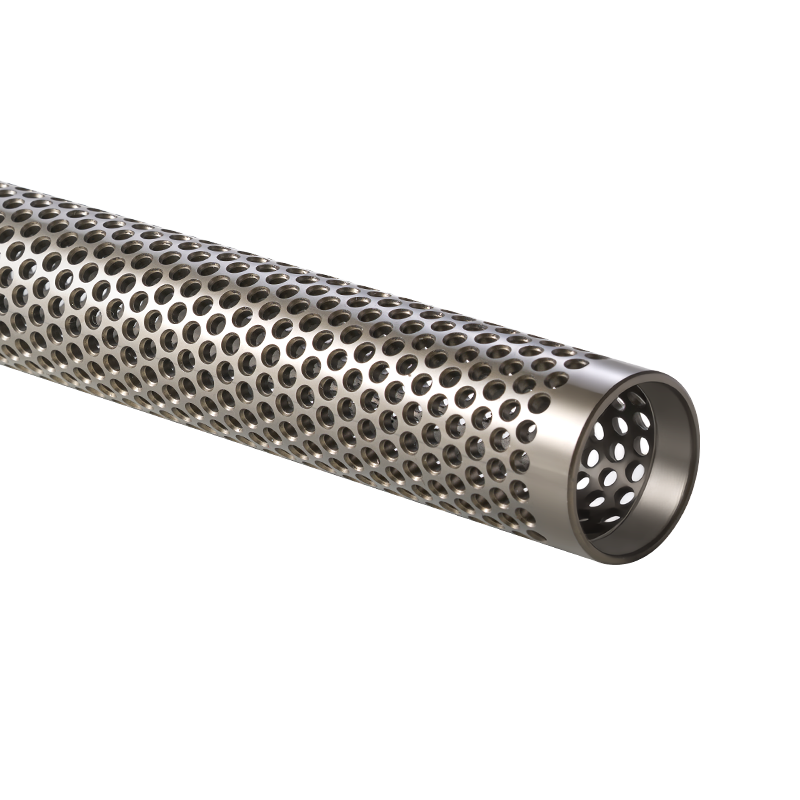

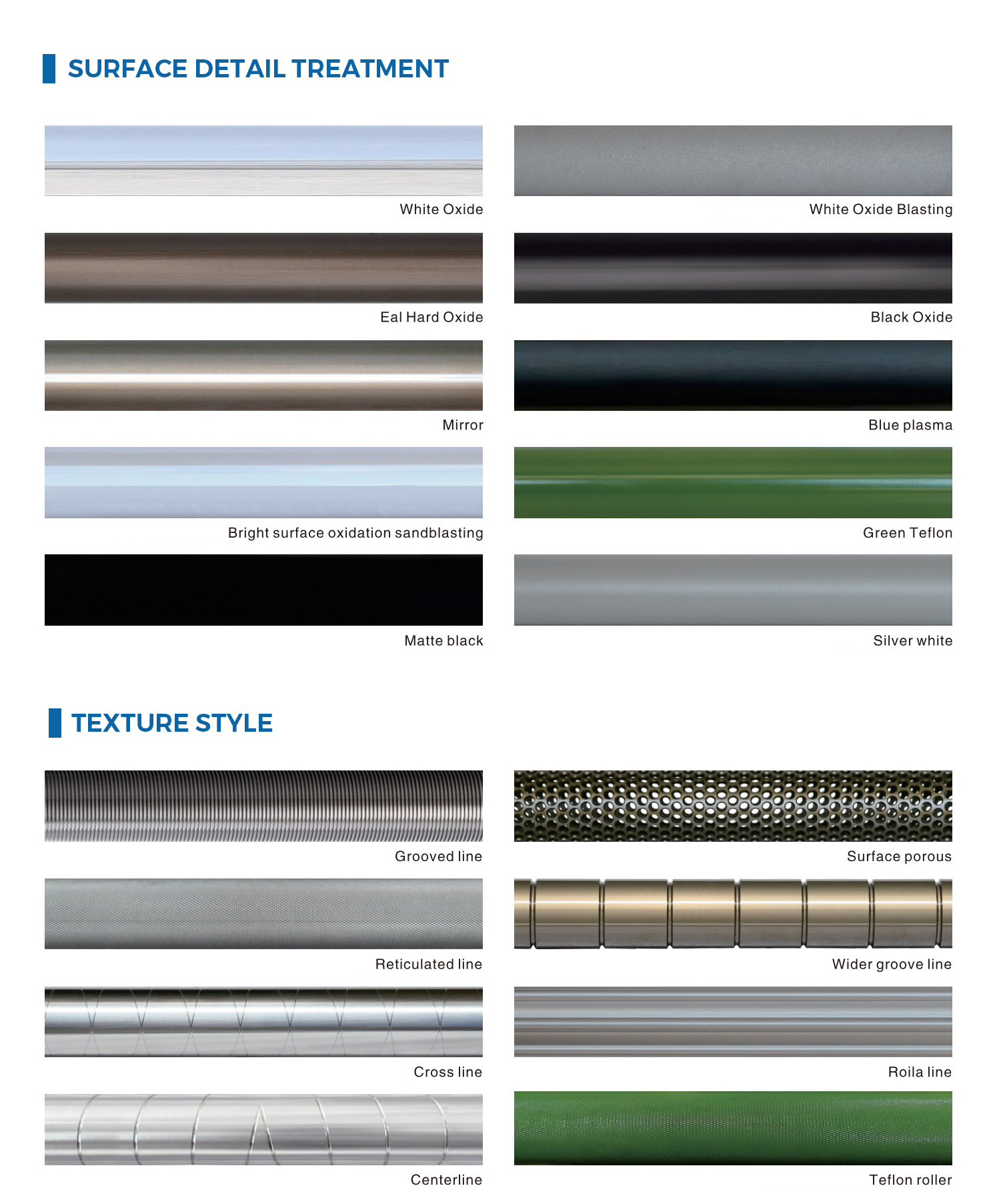

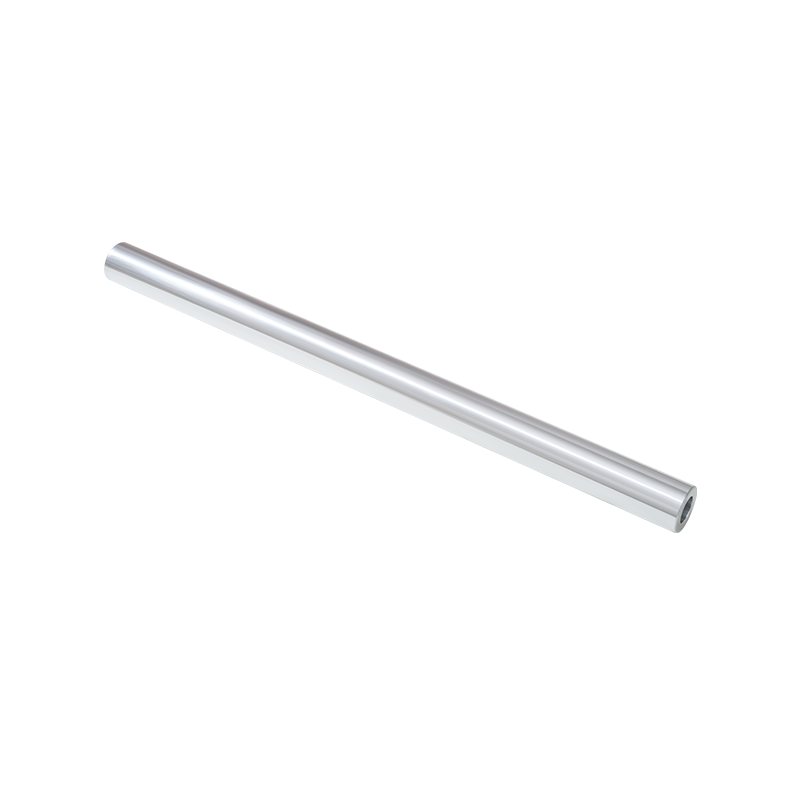

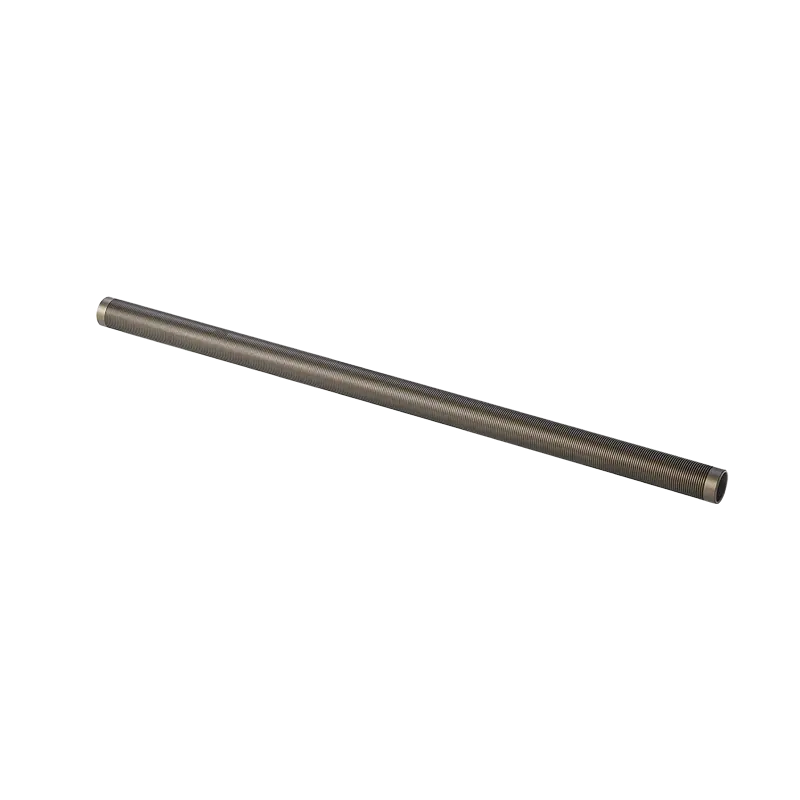

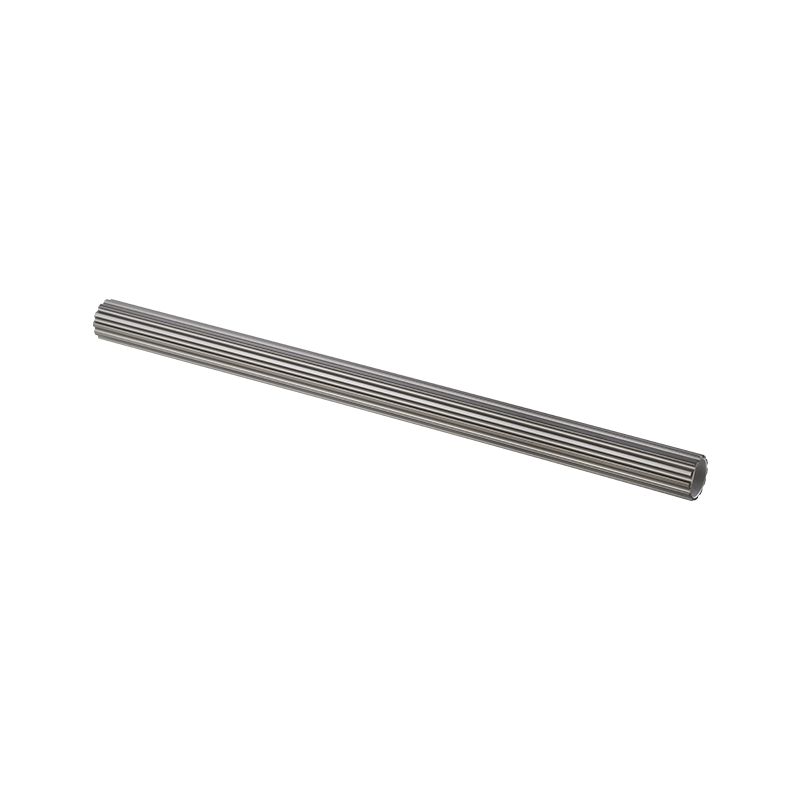

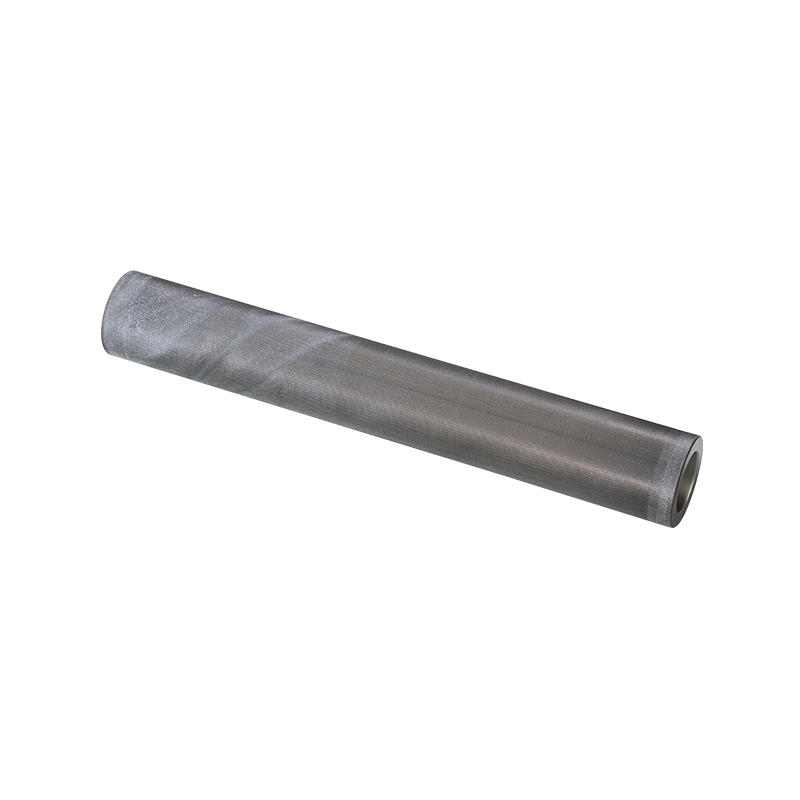

As a professional aluminum guide roller manufacturer, we can customize the pore diameter, hole spacing, length, and shaft end configuration to meet customer needs, flexibly adapting to diverse equipment and process requirements. Each guide roller undergoes dynamic balancing and surface treatments (such as anodizing) to ensure high strength, precision, and durability.

Our product is widely used in printing presses, laminating machines, slitting equipment, and coating lines, particularly where high air permeability, stable support, and precise positioning are required. Choosing our porous aluminum guide rollers combines lightweight design with good thermal conductivity and heat dissipation, along with flexible customization.

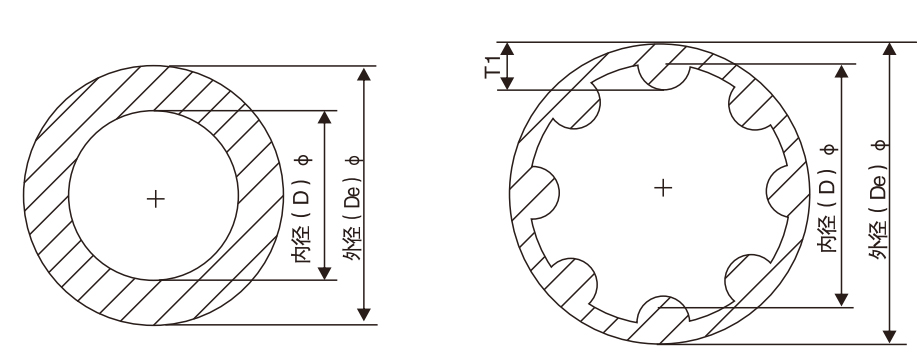

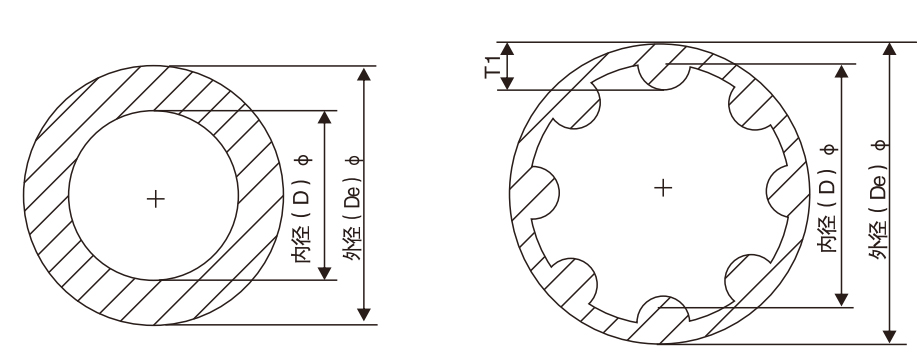

| (De)Φ |

(D)Φ |

THICKNESS |

T1 |

T2,T3 |

Number of stiffeners |

| Φ22 |

Φ16 |

3 |

|

◉ |

|

| Φ25 |

Φ20 |

2.5 |

|

◉ |

|

| Φ31 |

Φ23 |

4 |

|

◉ |

|

| Φ31 |

Φ25 |

3 |

|

◉ |

|

| Φ34 |

Φ26 |

4 |

|

◉ |

|

| Φ38 |

Φ30 |

4 |

|

◉ |

|

| Φ40 |

Φ30 |

5 |

|

◉ |

|

| Φ43 |

Φ33 |

5 |

|

▲ |

|

| Φ50 |

Φ40 |

5 |

|

▲ |

|

| Φ55 |

Φ45 |

5 |

|

▲ |

|

| Φ57 |

Φ50 |

3.5 |

|

▲ |

|

| Φ59 |

Φ50 |

4.5 |

|

▲ |

|

| Φ60 |

Φ50 |

5 |

10 |

▲ |

6 |

| Φ70 |

Φ61 |

4.5 |

10 |

▲ |

6 |

| Φ75 |

Φ66 |

4.5 |

10 |

▲ |

6 |

| Φ81 |

Φ71 |

5 |

10 |

▲ |

8 |

| Φ91 |

Φ81 |

5 |

10 |

▲ |

8 |

| Φ101 |

Φ91 |

5 |

11 |

▲ |

8 |

| Φ101 |

Φ87 |

7 |

11 |

▲ |

8 |

| Φ111 |

Φ99 |

6 |

12 |

▲ |

8 |

| Φ121 |

Φ109 |

6 |

12 |

▲ |

9 |

| Φ131 |

Φ118 |

6.5 |

13 |

▲ |

9 |

| Φ141 |

Φ128 |

6.5 |

13 |

▲ |

9 |

| Φ151 |

Φ137 |

7 |

14 |

▲ |

9 |

| Φ201 |

Φ179 |

11 |

|

|

|

| Φ300 |

Φ270 |

15 |

|

|

|

Español

Español Deutsch

Deutsch

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More