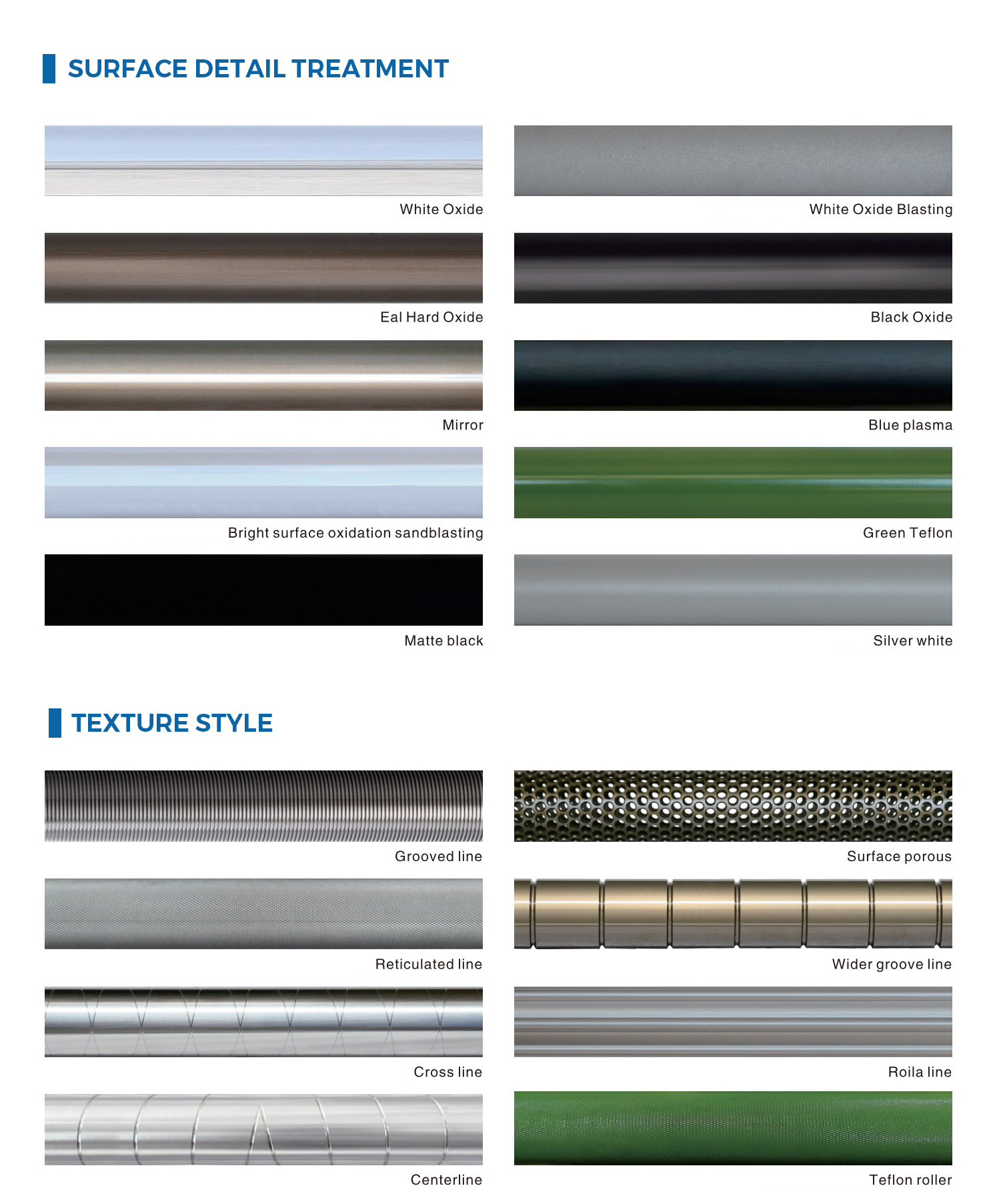

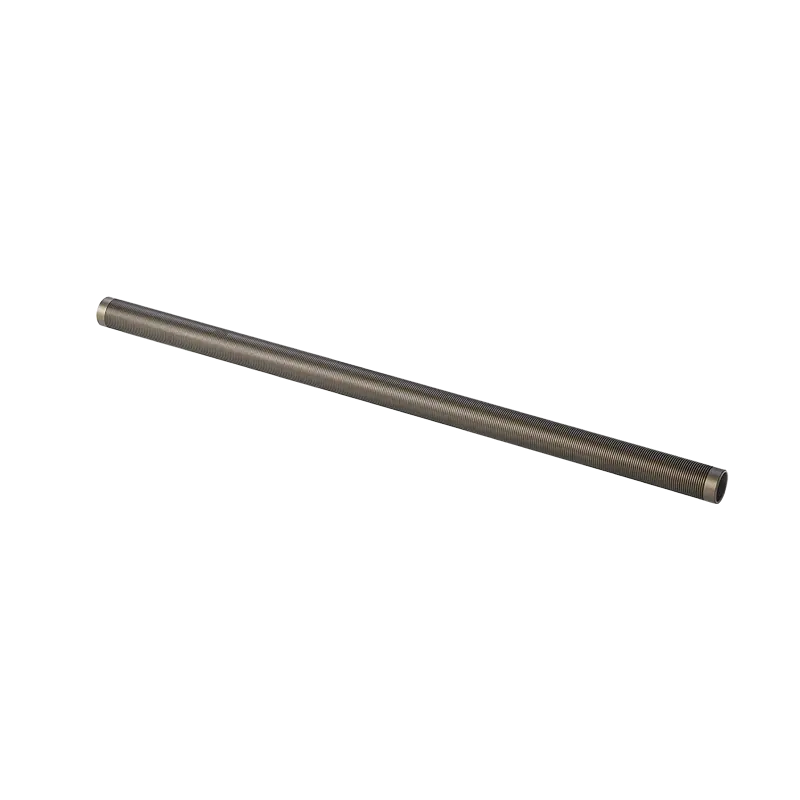

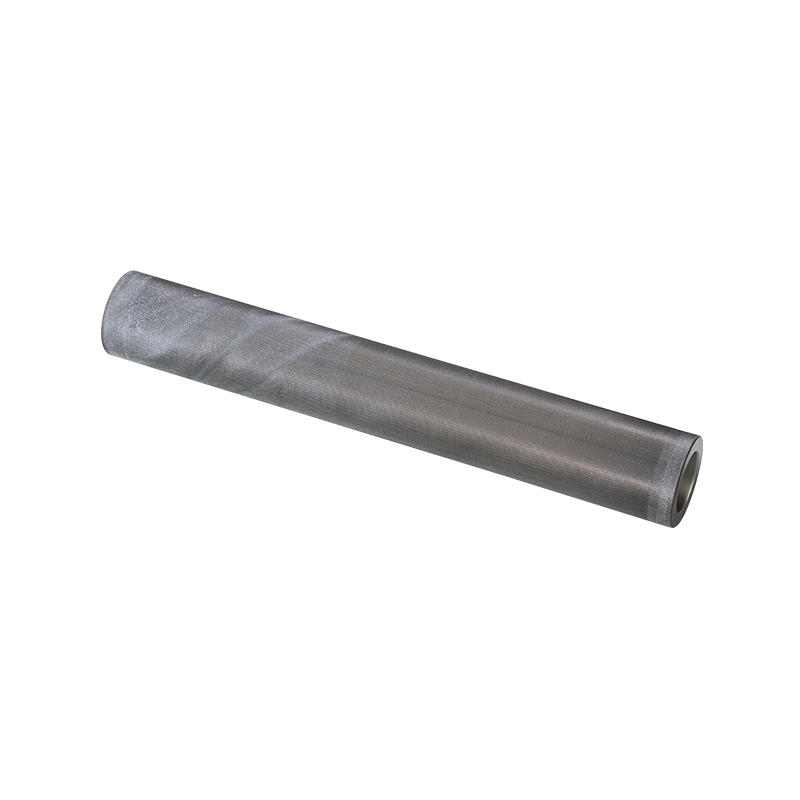

The roller surface undergoes a hard anodizing treatment, achieving an oxide film thickness exceeding 0.1mm and a surface hardness of HV700, significantly enhancing scratch, wear, and corrosion resistance. Compared to conventional anodizing treatments, hard anodizing not only extends service life but also provides superior performance in processing high-tension, thick webs.

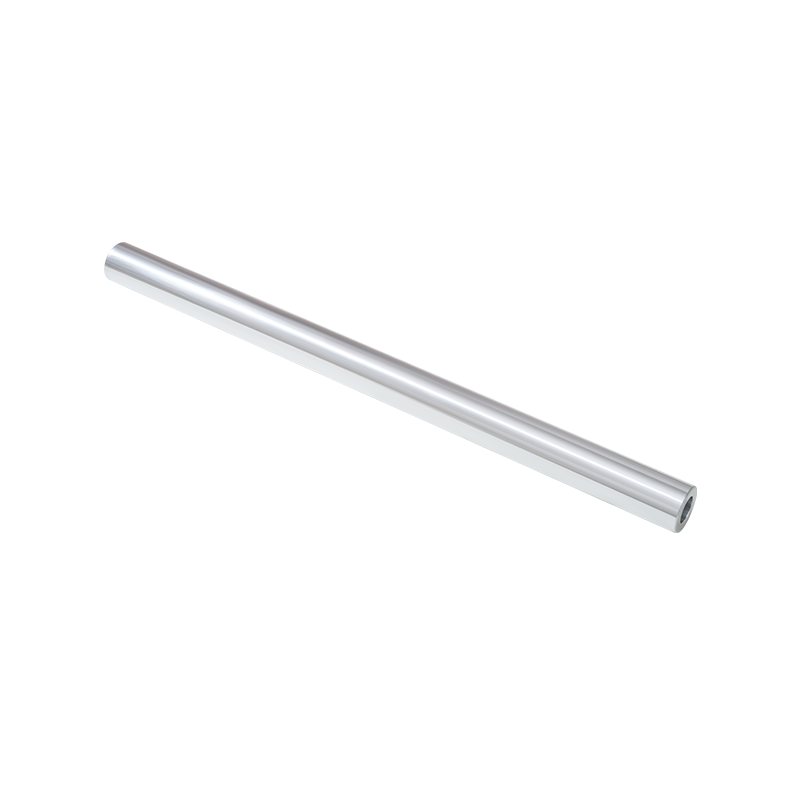

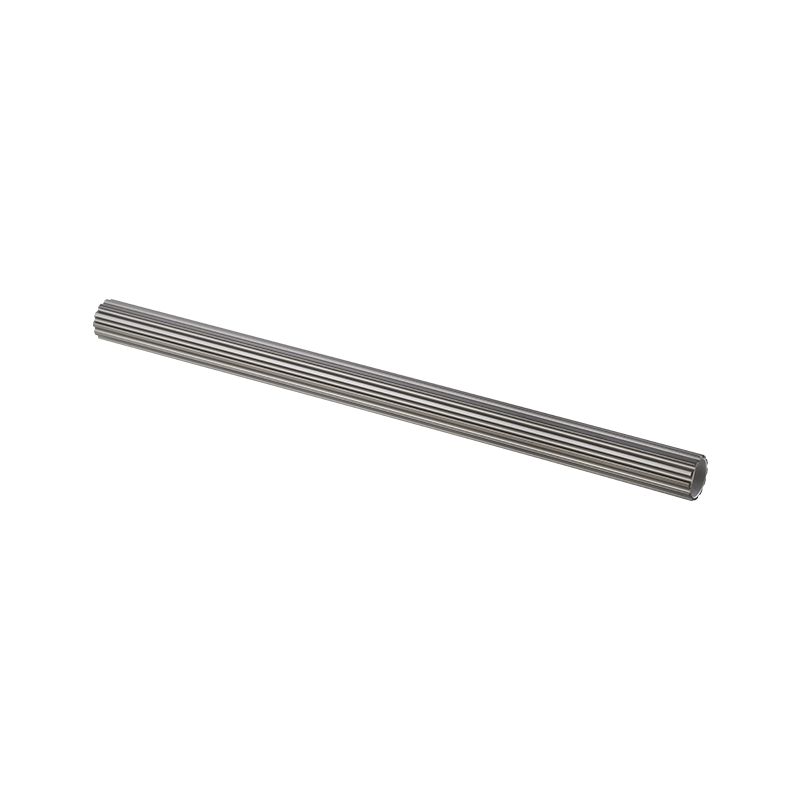

The smooth, unpatterned surface reduces running resistance, ensuring smooth and even web conveying and minimizing frictional losses. Internal ribs enhance overall strength, while high-precision machining and computerized dynamic balancing (within 2g) ensure smooth, vibration-free operation even at high speeds.

Our hard anodized aluminum guide roller is ideal for use in printing presses, coating machines, laminating machines, papermaking machinery, and other applications requiring high precision and wear resistance.

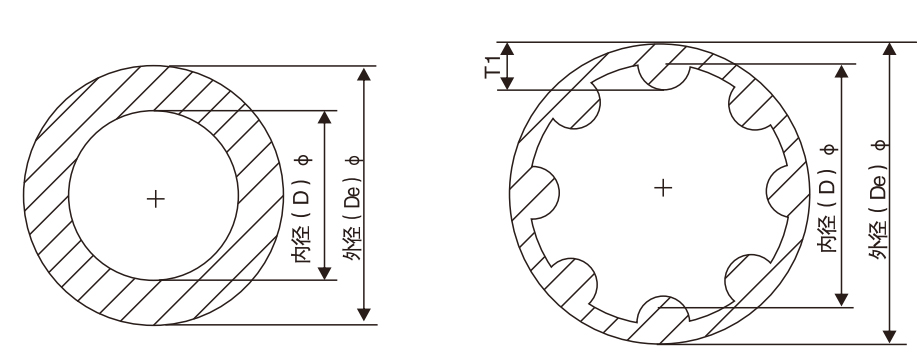

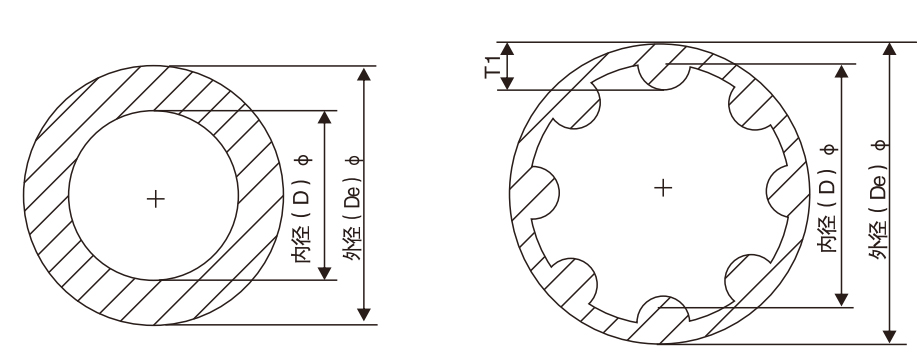

| (De)Φ |

(D)Φ |

THICKNESS |

T1 |

T2,T3 |

Number of stiffeners |

| Φ22 |

Φ16 |

3 |

|

◉ |

|

| Φ25 |

Φ20 |

2.5 |

|

◉ |

|

| Φ31 |

Φ23 |

4 |

|

◉ |

|

| Φ31 |

Φ25 |

3 |

|

◉ |

|

| Φ34 |

Φ26 |

4 |

|

◉ |

|

| Φ38 |

Φ30 |

4 |

|

◉ |

|

| Φ40 |

Φ30 |

5 |

|

◉ |

|

| Φ43 |

Φ33 |

5 |

|

▲ |

|

| Φ50 |

Φ40 |

5 |

|

▲ |

|

| Φ55 |

Φ45 |

5 |

|

▲ |

|

| Φ57 |

Φ50 |

3.5 |

|

▲ |

|

| Φ59 |

Φ50 |

4.5 |

|

▲ |

|

| Φ60 |

Φ50 |

5 |

10 |

▲ |

6 |

| Φ70 |

Φ61 |

4.5 |

10 |

▲ |

6 |

| Φ75 |

Φ66 |

4.5 |

10 |

▲ |

6 |

| Φ81 |

Φ71 |

5 |

10 |

▲ |

8 |

| Φ91 |

Φ81 |

5 |

10 |

▲ |

8 |

| Φ101 |

Φ91 |

5 |

11 |

▲ |

8 |

| Φ101 |

Φ87 |

7 |

11 |

▲ |

8 |

| Φ111 |

Φ99 |

6 |

12 |

▲ |

8 |

| Φ121 |

Φ109 |

6 |

12 |

▲ |

9 |

| Φ131 |

Φ118 |

6.5 |

13 |

▲ |

9 |

| Φ141 |

Φ128 |

6.5 |

13 |

▲ |

9 |

| Φ151 |

Φ137 |

7 |

14 |

▲ |

9 |

| Φ201 |

Φ179 |

11 |

|

|

|

| Φ300 |

Φ270 |

15 |

|

|

|

Español

Español Deutsch

Deutsch

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More