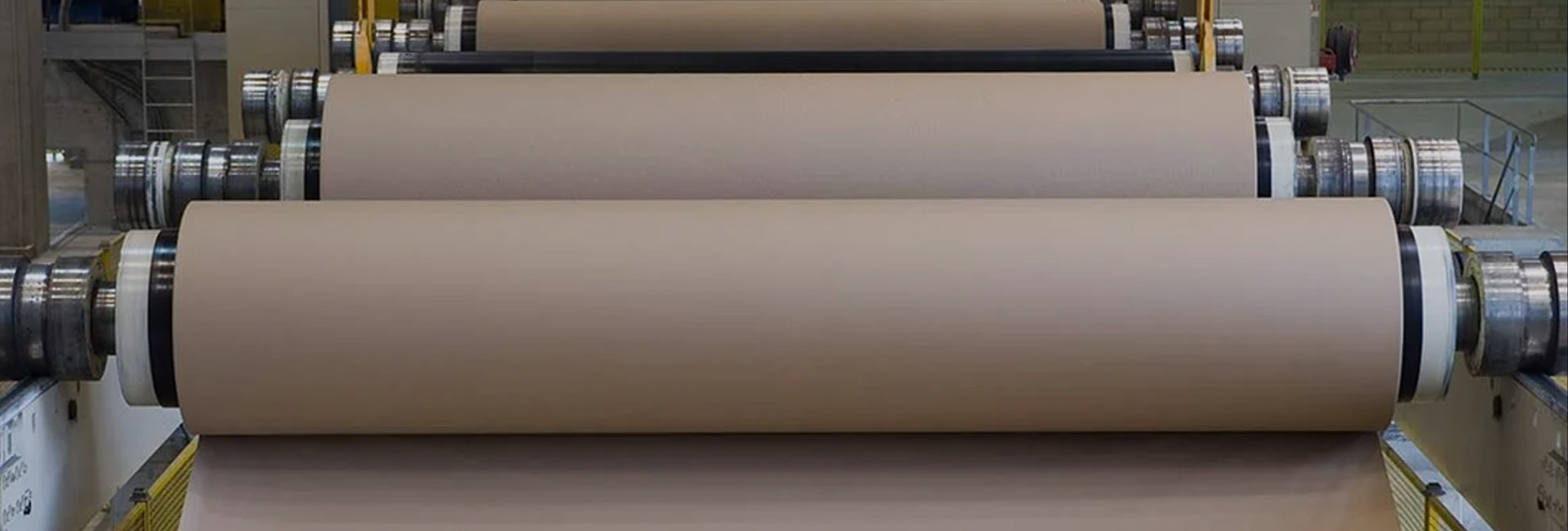

Paper Industry

Baixiao offers a complete range of roller solutions for paper processing—from cultural and specialty papers to tissue and packaging board—significantly enhancing surface treatment quality and production efficiency.

Core Industry Challenges

Paper warping and burring during high-speed slitting

Tension control difficulties when rewinding thin papers

Uneven transfer during surface treatment of specialty papers

Inefficient equipment adaptation during frequent product changeovers

Baixiao Solutions

Anti-static rollers: Prevent paper sticking and ensure smooth transfer

Micro-engraved roller surfaces: Deliver optimal air permeability and pressure distribution

Quick-change inflatable sleeves: Reduce roll replacement time to under 2 minutes

Typical Applications:

Tissue paper finishing: Complete solutions for creping, embossing, and rewinding to balance softness and bulk

Cultural paper supercalendering: High-precision chilled cast iron rollers provide uniform linear pressure for over 90° gloss finish

Packaging board lamination: Heavy-duty steel guide rollers with H13-grade bending strength (ISO 9001:2008 compliant) ensure smooth handling of thick cardboard

Specialty paper impregnation: Chemical-resistant Teflon rollers withstand resin and coating corrosion, tripling service life

Why Choose Baixiao Roller Systems?

Deep Industry Knowledge: 20 years of specialized expertise in paper and packaging machinery

Precision Performance Matching: Tailored configurations based on equipment models, material properties, and process needs

End-to-End Quality Control: 26 strict quality checkpoints from material selection to dynamic balancing

Rapid Service Support: 24/7 technical consultation and 72-hour emergency production response

Español

Español Deutsch

Deutsch