What Advantages Do Rubber Rollers Offer Compared to Metal Rollers?

Rubber rollers provide distinct benefits over traditional metal rollers, such as steel or aluminum, especially in material handling and processing applications. From a manufacturer’s perspective, these advantages include:

- Improved Grip and Traction: The elastic surface of rubber rollers enhances contact with the material, preventing slippage and ensuring precise movement along conveyor or processing lines.

- Vibration Dampening: Rubber absorbs shocks and vibrations, reducing stress on machinery and improving operational stability.

- Noise Reduction: Unlike metal rollers, rubber rollers operate quietly, which is crucial in environments where noise control is important.

- Material Protection: Rubber surfaces prevent surface damage to delicate materials, such as films, paper, textiles, and coated products.

- Corrosion Resistance: Rubber is less susceptible to corrosion than steel, making it suitable for humid or chemical-exposed environments.

- Energy Efficiency: Reduced slippage and smoother operation, lower energy consumption, and improved overall efficiency.

These characteristics make rubber rollers an essential component in industries like printing, packaging, and material handling.

How Can Manufacturers Select Rubber Coated Conveyor Drive Rollers Based on Hardness?

Choosing the appropriate hardness of rubber for conveyor drive rollers is critical to ensure performance, durability, and compatibility with the material being conveyed. Key considerations include:

- Material Type: Softer rubber (lower Shore A values) is ideal for delicate materials requiring gentle handling, whereas harder rubber (higher Shore A values) suits heavier loads or abrasive products.

- Load Capacity: Harder rubber coatings can withstand higher loads without deformation, preventing roller wear and slippage.

- Environmental Factors: Temperature, humidity, and exposure to chemicals can affect rubber performance. Selecting a formulation resistant to these conditions prolongs roller life.

- Operational Speed: High-speed conveyors may require firmer rubber to maintain consistent traction without excessive wear.

- Maintenance and Replacement: Manufacturers should consider ease of re-covering or replacing the rubber coating to decrease downtime.

Proper selection of Rubber Coated Conveyor Drive Rollers ensures reliable performance, reduced maintenance costs, and consistent material handling.

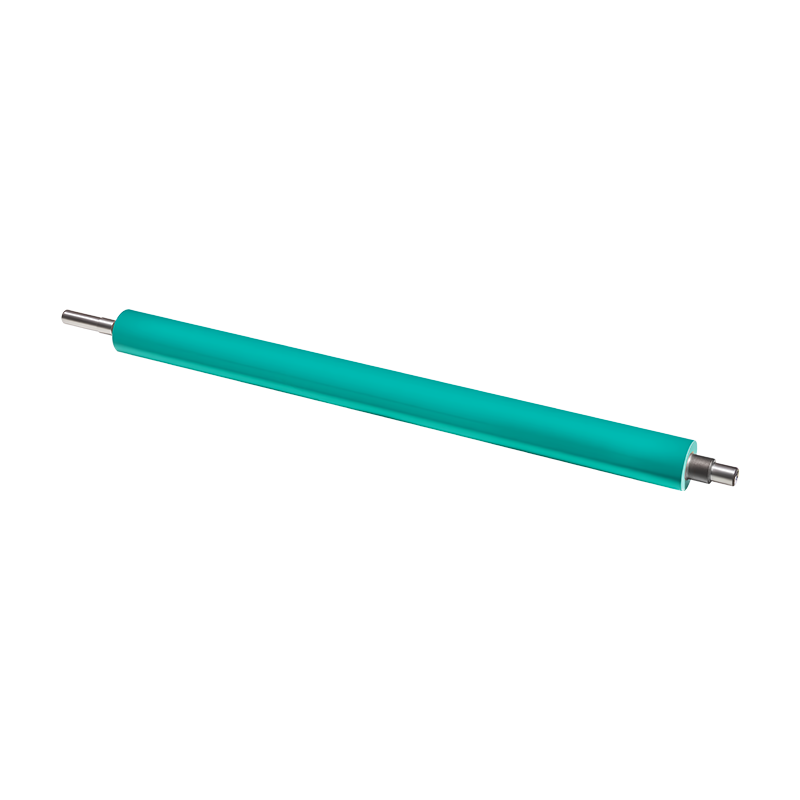

How Do Rubber-Covered Rollers Function in Calendering, Coating, and Laminating Processes?

Rubber-covered rollers play a vital role in processes such as calendering, coating, and laminating, where precise pressure and uniform contact are required. Their operation involves several critical aspects:

- Pressure Application: The elasticity of the rubber ensures even pressure across the web or substrate, critical for uniform coating or lamination.

- Material Conformity: Rubber surfaces conform slightly to surface irregularities, providing better contact and reducing defects.

- Friction Control: Controlled friction allows smooth material movement without slipping, preventing wrinkles or misalignment.

- Thermal Resistance: Certain rubber compounds can withstand elevated temperatures encountered in laminating or curing processes.

- Chemical Resistance: Rubber formulations are selected to resist inks, adhesives, or solvents used in coating or laminating operations.

By integrating Rubber Covered Rollers, manufacturers can maintain consistent quality, reduce waste, and optimize process efficiency.

How Can Proper Roller Selection Improve Manufacturing Efficiency?

Selecting the right type of roller—Rubber Roller, Rubber Coated Conveyor Drive Rollers, or Rubber Covered Rollers—provides multiple operational advantages:

- Enhanced Product Quality: Properly matched rollers reduce surface defects and ensure even coating, lamination, or conveyance.

- Reduced Maintenance Costs: Durable rubber surfaces reduce wear and allow longer intervals between replacements.

- Operational Reliability: Improved grip, traction, and vibration dampening prevent downtime due to slippage or misalignment.

- Energy Savings: Efficient material transfer reduces motor load and overall energy consumption.

- Process Flexibility: Rubber rollers can handle a wide variety of materials and applications, allowing manufacturers to adapt to changing production needs.

High-quality rubber rollers and coatings ensure that industrial processes operate smoothly, safely, and efficiently, enhancing both productivity and product quality.

Español

Español Deutsch

Deutsch