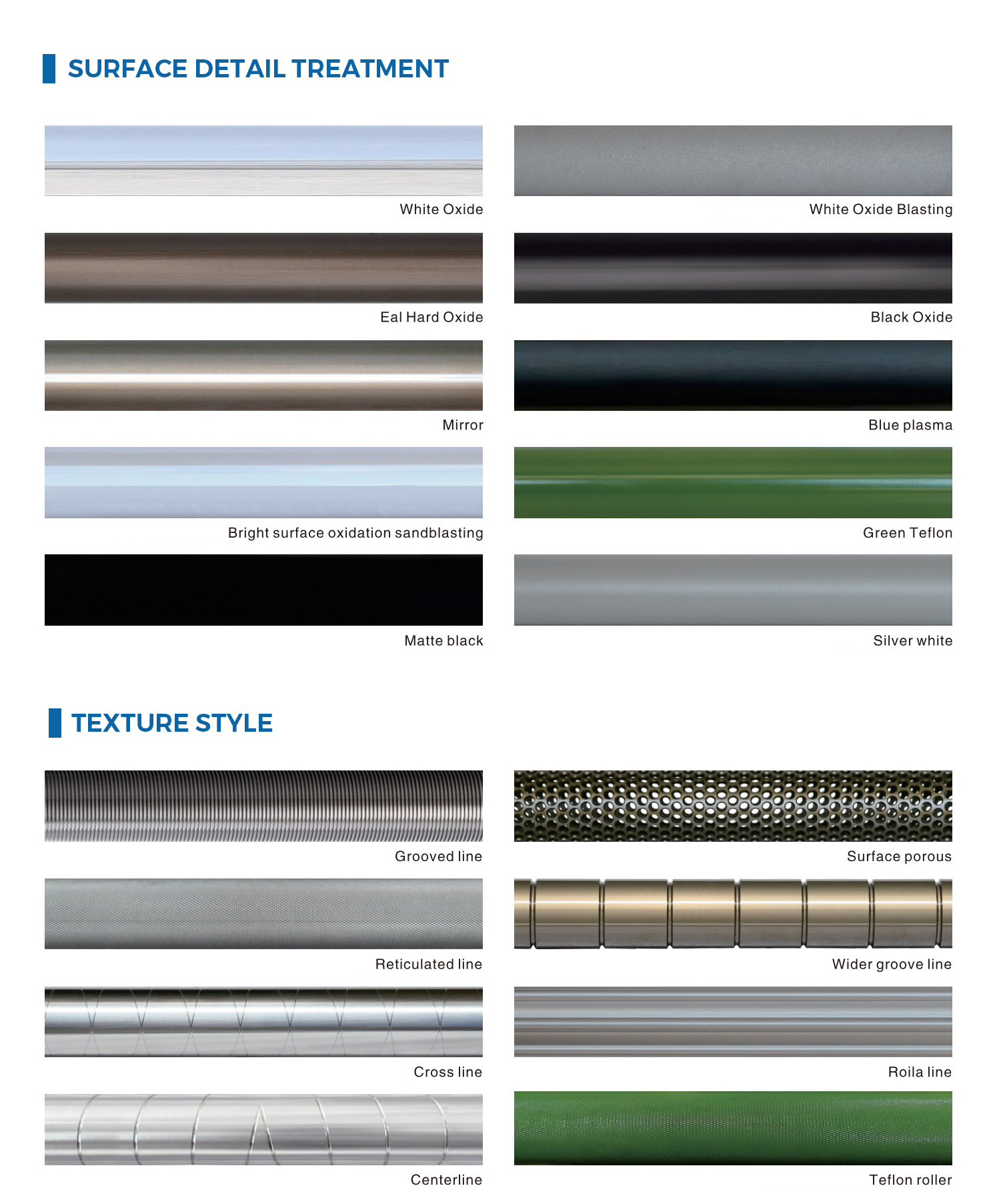

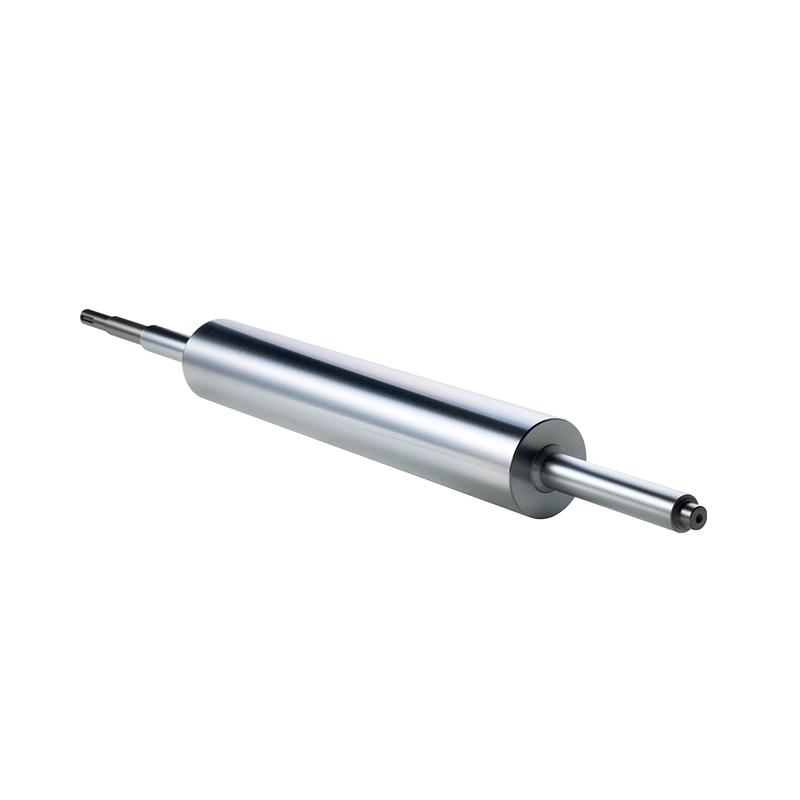

Segmented Structure Design: The roller surface consists of multiple grooved segments, allowing for flexible configuration of contact area to meet different material or process requirements.

Excellent Anti-slip and Guiding Performance: The grooves enhance friction, preventing roll material slippage and improving conveyor smoothness.

High Strength and Wear Resistance: Constructed from high-quality alloy steel or stainless steel, the roller surface undergoes heat treatment or plating processes to enhance durability.

Thermal Expansion Control: The segmented structure helps alleviate thermal stress concentration, maintaining stable roller deformation.

Customizable Processing: Groove width, depth, and number of segments can be customized according to equipment and material characteristics.

Typical Applications: Widely used in film, paper, nonwoven fabric, rubber, and composite material production lines, particularly suitable for high-precision roll material processing processes such as slitting, coating, and rewinding.

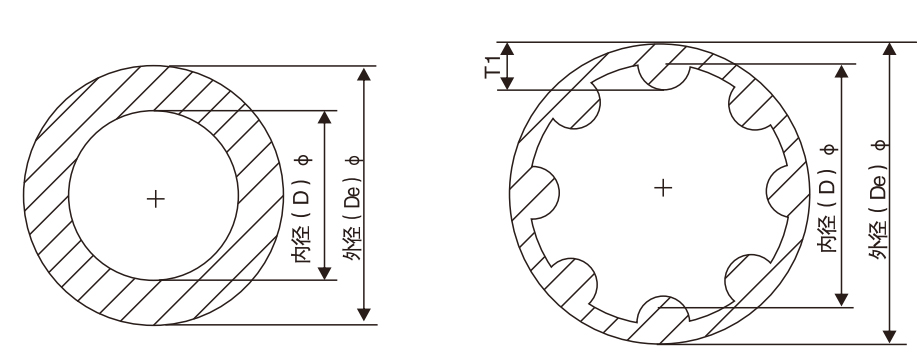

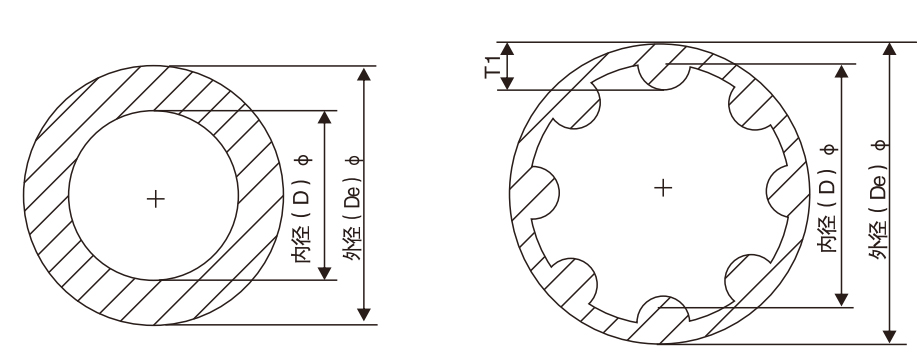

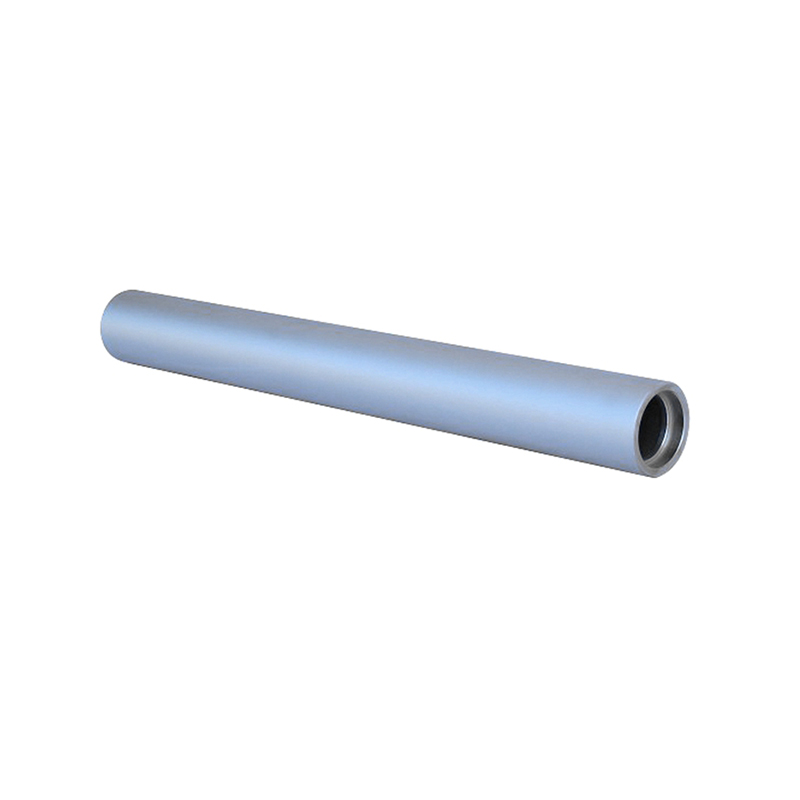

| (De)Φ |

(D)Φ |

THICKNESS |

T1 |

T2,T3 |

Number of stiffeners |

| Φ22 |

Φ16 |

3 |

|

◉ |

|

| Φ25 |

Φ20 |

2.5 |

|

◉ |

|

| Φ31 |

Φ23 |

4 |

|

◉ |

|

| Φ31 |

Φ25 |

3 |

|

◉ |

|

| Φ34 |

Φ26 |

4 |

|

◉ |

|

| Φ38 |

Φ30 |

4 |

|

◉ |

|

| Φ40 |

Φ30 |

5 |

|

◉ |

|

| Φ43 |

Φ33 |

5 |

|

▲ |

|

| Φ50 |

Φ40 |

5 |

|

▲ |

|

| Φ55 |

Φ45 |

5 |

|

▲ |

|

| Φ57 |

Φ50 |

3.5 |

|

▲ |

|

| Φ59 |

Φ50 |

4.5 |

|

▲ |

|

| Φ60 |

Φ50 |

5 |

10 |

▲ |

6 |

| Φ70 |

Φ61 |

4.5 |

10 |

▲ |

6 |

| Φ75 |

Φ66 |

4.5 |

10 |

▲ |

6 |

| Φ81 |

Φ71 |

5 |

10 |

▲ |

8 |

| Φ91 |

Φ81 |

5 |

10 |

▲ |

8 |

| Φ101 |

Φ91 |

5 |

11 |

▲ |

8 |

| Φ101 |

Φ87 |

7 |

11 |

▲ |

8 |

| Φ111 |

Φ99 |

6 |

12 |

▲ |

8 |

| Φ121 |

Φ109 |

6 |

12 |

▲ |

9 |

| Φ131 |

Φ118 |

6.5 |

13 |

▲ |

9 |

| Φ141 |

Φ128 |

6.5 |

13 |

▲ |

9 |

| Φ151 |

Φ137 |

7 |

14 |

▲ |

9 |

| Φ201 |

Φ179 |

11 |

|

|

|

| Φ300 |

Φ270 |

15 |

|

|

|

Español

Español Deutsch

Deutsch

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More