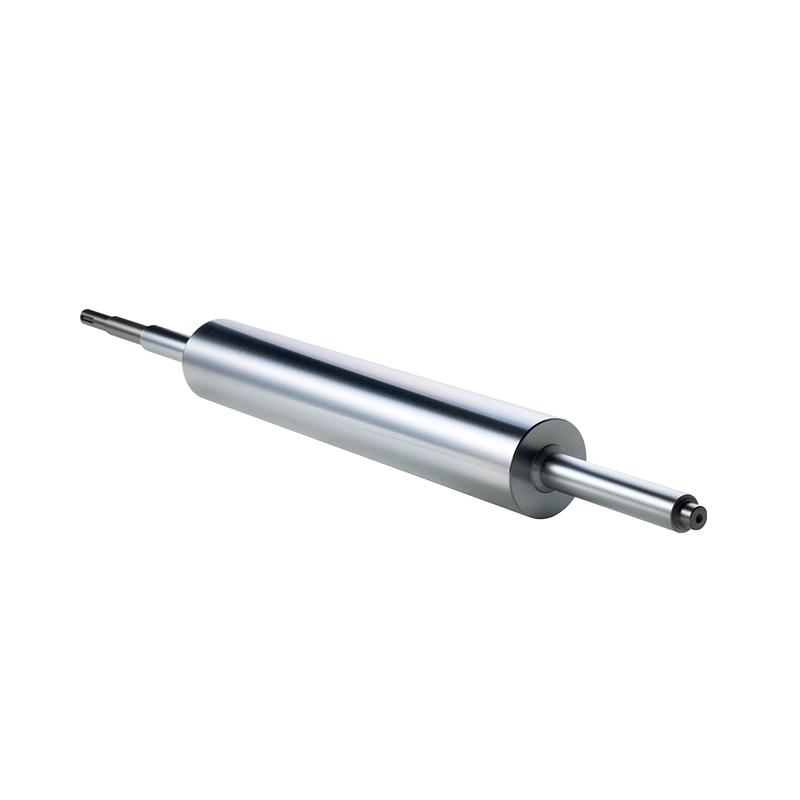

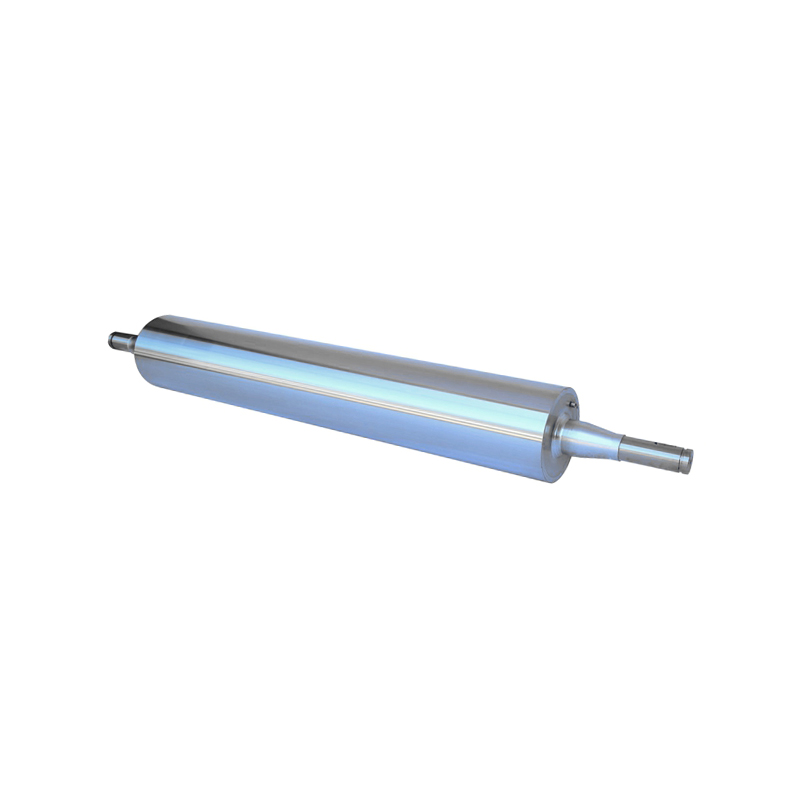

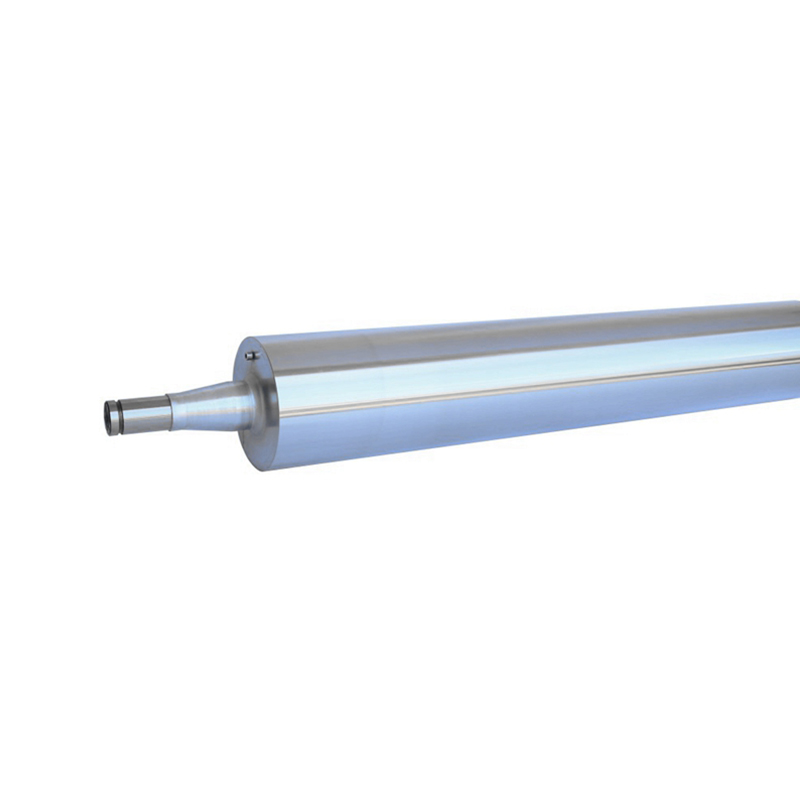

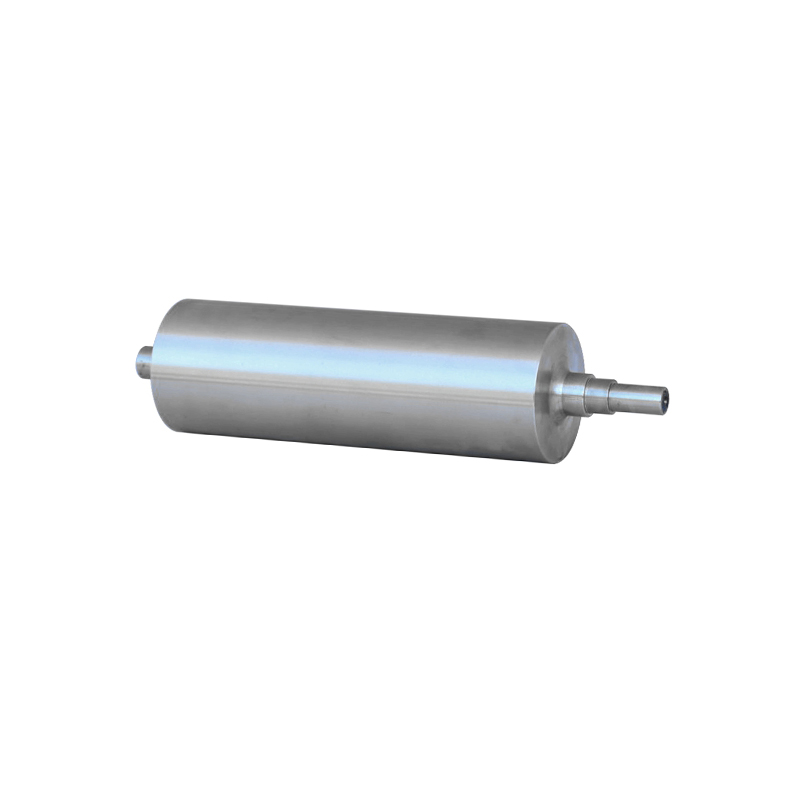

Hard chrome-plated steel rollers are sturdy and capable of withstanding heavy loads, making them suitable for a wide range of industrial production applications, including calendering, conveying, coating, papermaking, printing, and plastic film production. Their high surface hardness and low coefficient of friction effectively reduce wear and scratches during material processing, improving product surface quality and precision. Furthermore, the hard chrome layer adheres evenly to the roller surface, ensuring consistent pressing results and significantly improving production efficiency and reliability.

Hard chrome-plated steel rollers offer a stable structure, long lifespan, simple maintenance, and good parts interchangeability, adapting to the installation and use requirements of a wide range of industrial equipment. With their high wear resistance, high precision, and good corrosion resistance, hard chrome-plated steel rollers have become crucial core components in modern manufacturing, enhancing processing quality, ensuring production efficiency, and extending equipment life.

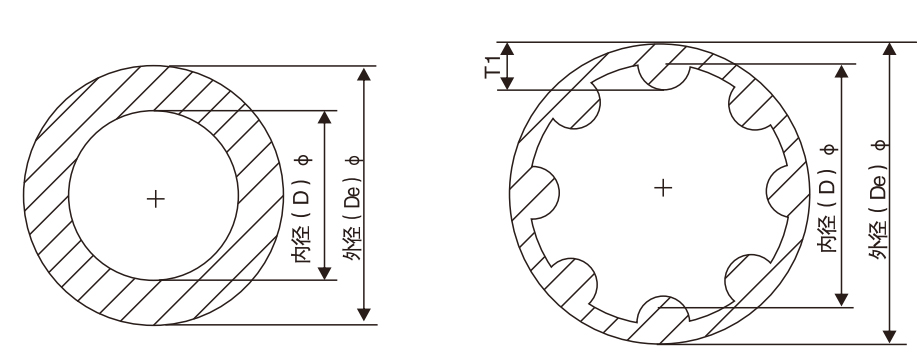

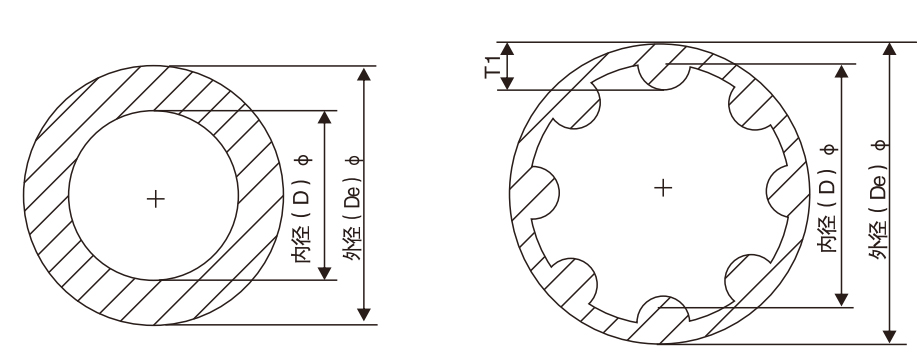

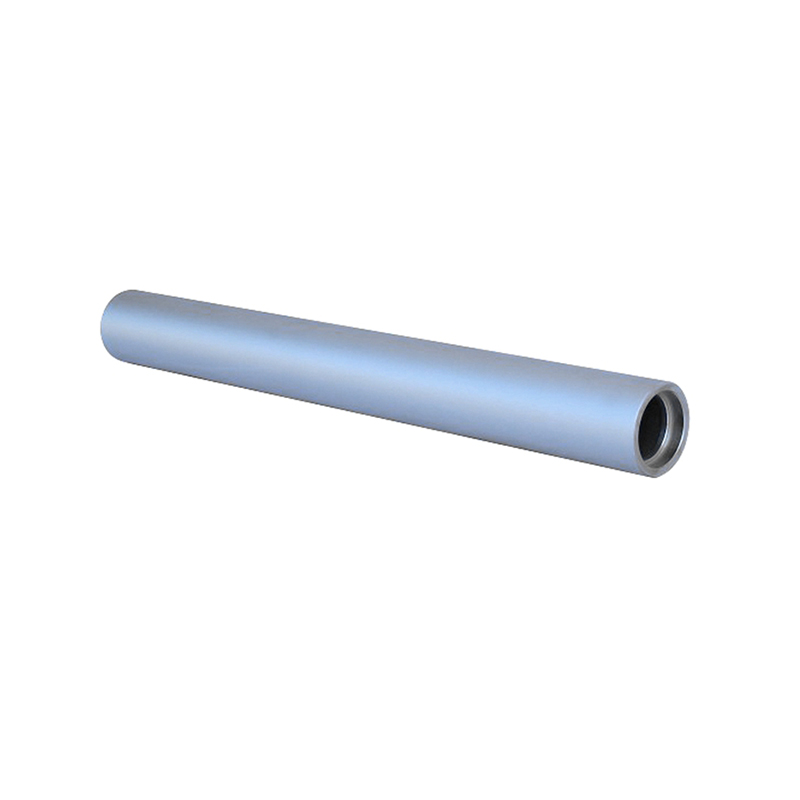

| (De)Φ |

(D)Φ |

THICKNESS |

T1 |

T2,T3 |

Number of stiffeners |

| Φ22 |

Φ16 |

3 |

|

◉ |

|

| Φ25 |

Φ20 |

2.5 |

|

◉ |

|

| Φ31 |

Φ23 |

4 |

|

◉ |

|

| Φ31 |

Φ25 |

3 |

|

◉ |

|

| Φ34 |

Φ26 |

4 |

|

◉ |

|

| Φ38 |

Φ30 |

4 |

|

◉ |

|

| Φ40 |

Φ30 |

5 |

|

◉ |

|

| Φ43 |

Φ33 |

5 |

|

▲ |

|

| Φ50 |

Φ40 |

5 |

|

▲ |

|

| Φ55 |

Φ45 |

5 |

|

▲ |

|

| Φ57 |

Φ50 |

3.5 |

|

▲ |

|

| Φ59 |

Φ50 |

4.5 |

|

▲ |

|

| Φ60 |

Φ50 |

5 |

10 |

▲ |

6 |

| Φ70 |

Φ61 |

4.5 |

10 |

▲ |

6 |

| Φ75 |

Φ66 |

4.5 |

10 |

▲ |

6 |

| Φ81 |

Φ71 |

5 |

10 |

▲ |

8 |

| Φ91 |

Φ81 |

5 |

10 |

▲ |

8 |

| Φ101 |

Φ91 |

5 |

11 |

▲ |

8 |

| Φ101 |

Φ87 |

7 |

11 |

▲ |

8 |

| Φ111 |

Φ99 |

6 |

12 |

▲ |

8 |

| Φ121 |

Φ109 |

6 |

12 |

▲ |

9 |

| Φ131 |

Φ118 |

6.5 |

13 |

▲ |

9 |

| Φ141 |

Φ128 |

6.5 |

13 |

▲ |

9 |

| Φ151 |

Φ137 |

7 |

14 |

▲ |

9 |

| Φ201 |

Φ179 |

11 |

|

|

|

| Φ300 |

Φ270 |

15 |

|

|

|

Español

Español Deutsch

Deutsch

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More

View More