In the field of color printing and packaging machinery,Ruian Baixiao Machinery Co., Ltd. has achieved rapid growth through continuous research and application of technology.,as a Custom Carbon Fiber Guide Roller Manufacturer and Wholesale Carbon Fiber Guide Roller Factory for over two decades, the company has been committed to technological improvement and scientific management, organizing production and sales with high standards, new technologies, and new equipment to enhance its ability to compete in the fiercely competitive market.

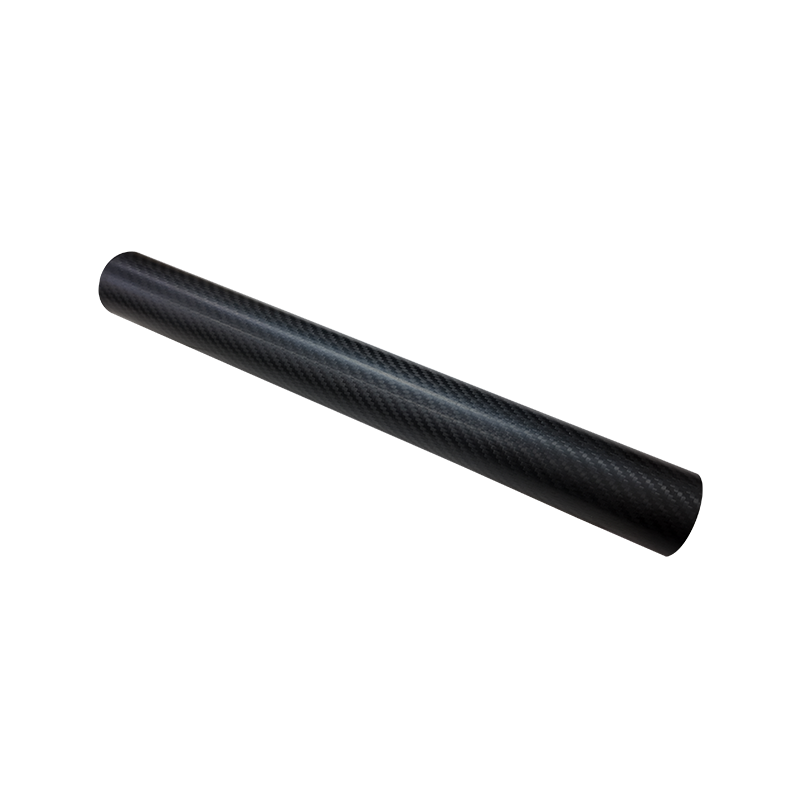

Our factory specializes in producing a wide range of supporting products for color printing, packaging, and various flexible packaging machinery, including aluminum guide rollers, air shafts, differential shafts, air sleeves, rubber rollers, drums, magnetic powder clutches, controllers, and other machinery. These products are sold nationwide. Our excellent quality and excellent after-sales service have earned us the trust and support of domestic and international customers. Our people-oriented company strives for survival through quality, development through innovation, and market success through integrity. We possess independent R&D capabilities, sophisticated processing equipment, and employ modern technology, along with scientific management, comprehensive testing methods, and a comprehensive quality assurance system. In 2010, Ruian Baixiao Machinery Co., Ltd. was awarded the title of "China Credit Enterprise Certification System Demonstration Unit" and "China Credit Enterprise Unit" by the China Internet News Center (sponsored by the China Internet Network Information Center, with guidance from the State Council Information Office's Network Publicity Bureau, the Ministry of Commerce's Market Operation Department, and the National Development and Reform Commission's International Cooperation Center).

Our factory adheres to the business philosophy of "technology-driven, pioneering, and reputation-based," striving to provide comprehensive and detailed technical services. We sincerely welcome new and existing customers, both domestic and international, to work together to achieve mutual success.

Español

Español Deutsch

Deutsch