Performance of Steel Roller Under Varying Loads

Importance of Load Performance

Steel rollers are critical components in conveyor systems, industrial machinery, and material handling equipment. Their performance under varying load conditions determines the efficiency, reliability, and lifespan of the entire system. Understanding how Steel Roller behaves under different weights and stresses helps engineers select the right roller for specific applications, ensuring consistent operation and reducing maintenance issues.

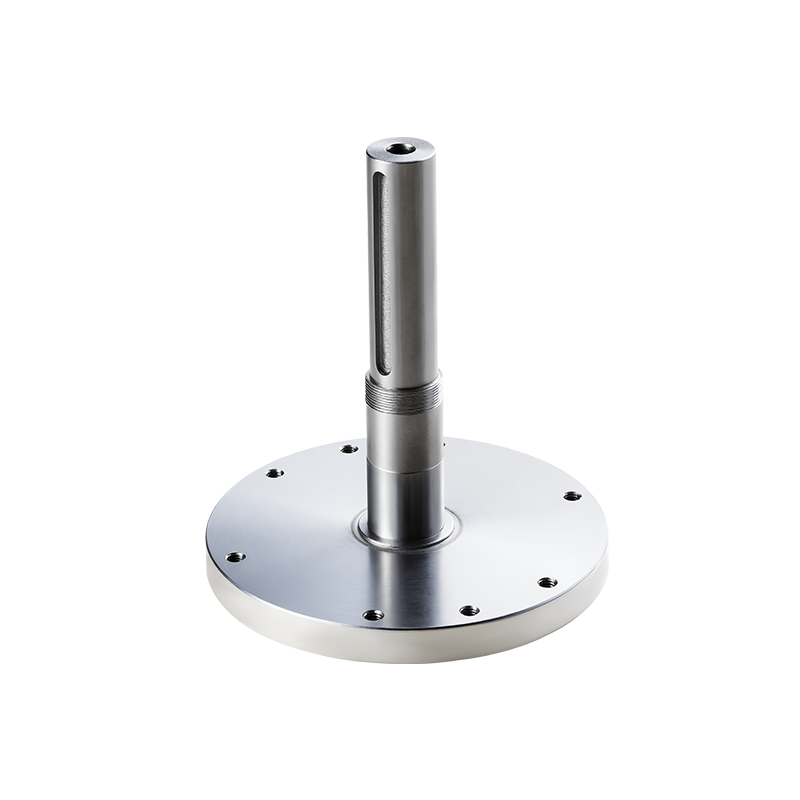

Material Strength and Load Capacity

The core factor influencing performance under load is the material used in the roller. Steel provides high tensile strength and rigidity, allowing it to handle medium to heavy loads without deforming. The selection of carbon steel, alloy steel, or stainless steel affects the roller’s load-bearing capacity and resistance to wear. A high-quality Steel Roller is designed to distribute the applied load evenly, reducing stress concentrations and preventing premature failure.

Diameter and Wall Thickness Considerations

The diameter and wall thickness of a Steel Roller are critical design parameters that influence its ability to handle varying loads. Larger diameters and thicker walls increase stiffness, allowing the roller to carry heavier weights with deflection. Smaller or thinner rollers may be suitable for lighter loads but are prone to bending or wobbling under excessive pressure. Manufacturers typically provide load ratings based on these specifications, guiding users in selecting rollers suitable for their operational requirements.

Bearing and Axle Performance

Steel Roller performance under load is also affected by its bearing and axle design. High-quality bearings reduce friction and enable smooth rotation even under heavy loads. The axle must be robust enough to support the roller without bending or misalignment. Proper lubrication further enhances performance and prevents overheating or excessive wear. Choosing the right combination of roller, axle, and bearing is essential to maintain operational stability across different load conditions.

Environmental and Operational Factors

Load performance is not only determined by material and design but also by environmental and operational factors. Temperature variations, humidity, and exposure to corrosive substances can impact the roller’s strength and durability. Continuous heavy loading or shock loads can accelerate wear and deformation. A well-engineered Steel Roller considers these factors, using materials and coatings that maintain structural integrity in demanding conditions.

Maintenance and Longevity

Regular inspection and maintenance are crucial to ensure consistent performance under varying loads. Checking for wear, misalignment, or bearing failure can prevent unexpected downtime. Steel Rollers are generally durable and capable of handling fluctuating loads over long periods, but maintenance practices such as cleaning, lubrication, and load monitoring can significantly extend their service life.

Applications Across Different Load Conditions

Steel Rollers are widely used in applications ranging from light conveyor systems to heavy industrial machinery. For light loads, the roller ensures smooth material movement with friction. Under medium to heavy loads, it provides stability and prevents bending or deformation, ensuring accurate alignment and operational efficiency. Understanding the specific load requirements and selecting the appropriate Steel Roller guarantees suitable performance and system reliability.

Reliable Performance Through Proper Selection

Steel Roller performance under different load conditions depends on material strength, roller diameter, wall thickness, bearing quality, and environmental considerations. By carefully selecting rollers designed to handle the expected loads and maintaining them properly, users can achieve smooth, efficient, and reliable operation across a wide range of industrial applications. A high-quality Steel Roller ensures durability, stability, and consistent performance, reducing maintenance costs and improving overall system efficiency.

Español

Español Deutsch

Deutsch