Air Shaft Factory Solutions for Material Tension Control

Air Shaft Tension Control in Packaging

In the packaging industry, precise material tension control is critical for ensuring product quality, reducing waste, and maintaining smooth production processes. Air shafts, commonly supplied by specialized manufacturers, play a vital role in achieving this control. By expanding inside the core of a roll, an air shaft securely grips the material, allowing it to be unwound or rewound with consistent tension. This capability is particularly important for thin films, paper, foil, and other flexible packaging materials that are prone to stretching, wrinkling, or misalignment during high-speed processing. Air Shaft Factory designs its products with features that provide both reliability and adaptability, making them essential components in modern packaging lines.

Mechanism of Air Shaft Tension Control

Air shafts control tension through their unique inflatable mechanism. When compressed air is introduced into the shaft, internal bladders or expansion segments inflate and press firmly against the inner diameter of the material roll. This action creates uniform radial pressure along the core, ensuring that the material remains securely in place during unwinding or rewinding. The ability to adjust air pressure allows operators to fine-tune the gripping force to match different material types, roll diameters, and production speeds. This adjustability prevents slipping or over-tightening, which can cause material deformation, edge damage, or uneven winding.

Importance of Packaging Processes

Maintaining proper tension throughout the packaging process is critical for several reasons. Consistent tension ensures precise registration and alignment in printing, laminating, or coating operations. Misaligned materials can result in defective packaging, wasted material, and additional downtime. Second, correct tension reduces the risk of wrinkles, stretching, or tearing, which are common issues with delicate or thin films. Finally, tension control contributes to the longevity of the packaging machinery itself. By reducing uneven stress on rollers and bearings, air shafts help prevent premature wear and maintenance requirements, improving overall production efficiency.

Design Features Supporting Tension Management

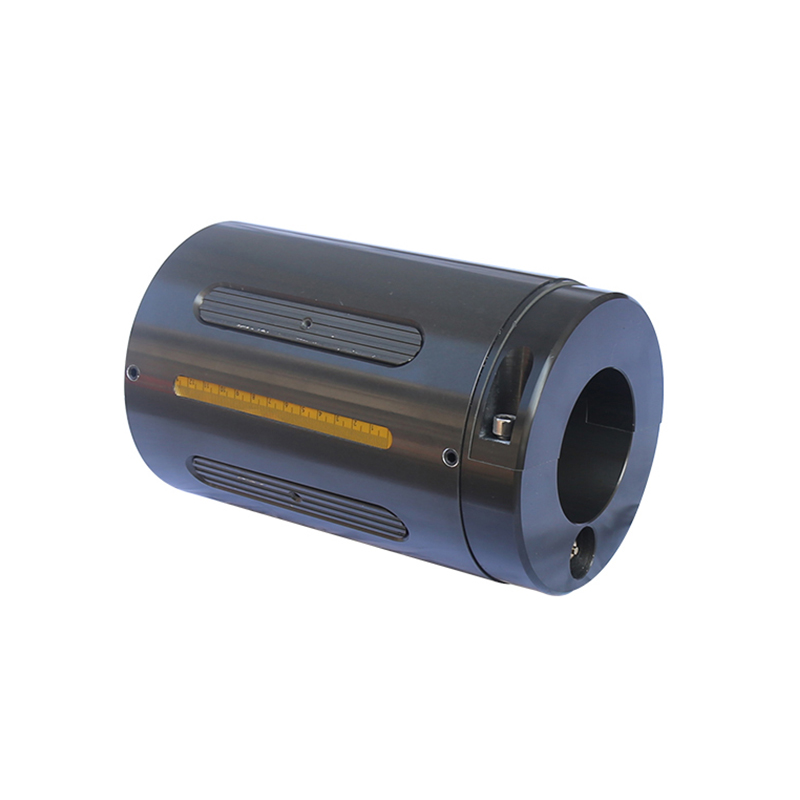

Air Shaft Factories incorporate several design features specifically to optimize tension control. High-quality bladders or inflatable segments ensure even expansion along the entire length of the shaft, preventing localized slippage. Some shafts feature multiple air zones or segmented inflation, allowing differential pressure adjustments for rolls with varying diameters. Materials used for the shaft body, such as anodized aluminum or carbon fiber, provide lightweight strength while reducing deflection under high tension. Precision-machined end hubs and seals ensure that air is evenly distributed, further enhancing consistent material grip.

Integration with Automated Packaging Systems

Modern packaging lines often operate at high speeds and require automated tension monitoring. Air shafts can be integrated with sensors and control systems to dynamically adjust inflation pressure in response to real-time tension readings. This feedback loop enables continuous, precise tension control without manual intervention, ensuring consistent quality across long production runs. Such integration is particularly important for complex packaging operations that combine printing, lamination, and slitting in a single line, where even small deviations in tension can result in significant defects.

Air Shaft Factories provide specialized products that are essential for material tension control in the packaging industry. By offering adjustable, reliable, and precisely engineered inflatable shafts, these manufacturers enable packaging lines to handle delicate materials efficiently while maintaining consistent product quality. Proper tension control reduces defects, reduces waste, and enhances production efficiency, making air shafts a cornerstone technology for modern packaging operations. Through thoughtful design, material selection, and integration with automated systems, air shafts continue to improve the reliability and performance of high-speed packaging processes.

Español

Español Deutsch

Deutsch