Specialized Sealing Matters for Conveyors in Dusty and Humid Environments?

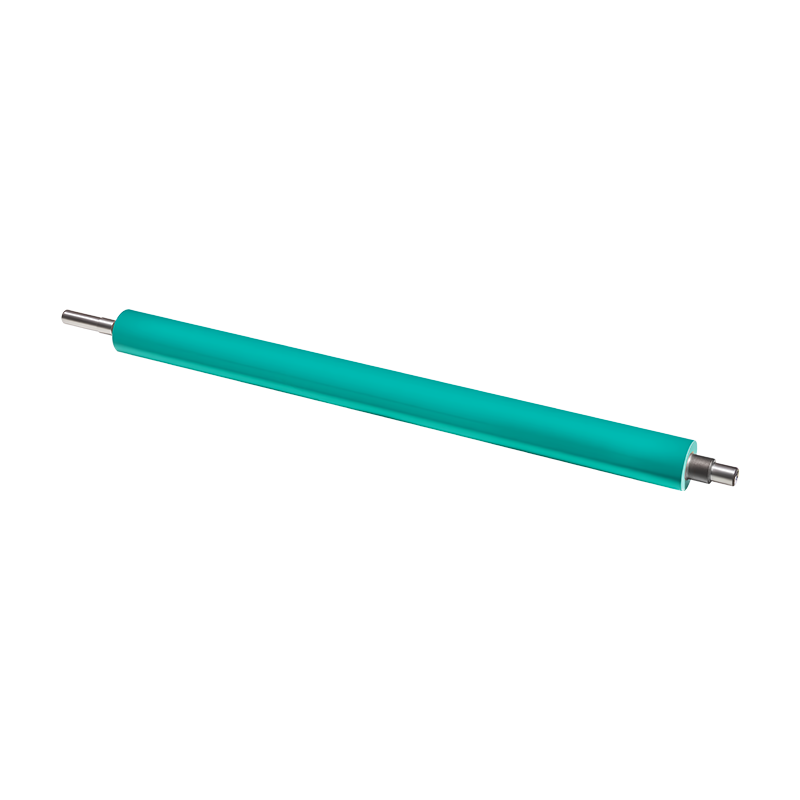

In many material-handling environments, systems such as Roller Track Conveyors, Skate Roller Conveyors, and Light Duty Roller Conveyors are widely used due to their simplicity, flexibility, and cost-effectiveness. These conveyors are often chosen for packaging lines, e-commerce sorting, small-load assembly processes, and manually operated transport sections. However, when these conveyors operate in dusty or humid environments, their performance and durability can be significantly affected if proper sealing strategies are not adopted. Dust particles, moisture, and airborne contaminants can penetrate roller assemblies, degrade bearing performance, increase resistance, and shorten overall service life.

The need for special sealing designs becomes even more critical when conveyors operate indoors near cutting, grinding, or mixing processes, or outdoors where humidity and condensation are unavoidable. Understanding how environmental factors affect roller components is crucial for selecting and reducing long-term maintenance costs.

Challenges Introduced by Dusty Environments

Dusty conditions pose one of the frequent and damaging threats to conveyor roller systems. The penetration of fine particles into bearings and moving parts can cause a wide range of performance issues.

1. Increased Friction and Bearing Contamination

- Dust particles easily infiltrate unsealed or poorly sealed roller housings.

- Once inside, particles mix with lubricants, creating abrasive compounds.

- This abrasive effect accelerates wear on bearing surfaces, balls, and races.

- Over time, the roller may begin to seize or exhibit significant resistance, reducing efficiency.

2. Roller Misalignment and Irregular Rotation

- Dust accumulation around the roller ends can cause uneven weight distribution.

- If the dust becomes compacted, it may create drag, slowing the roller unevenly.

- In a Light Duty Roller Conveyor, where force is often manual or gravity-driven, even minor drag can disrupt consistent flow.

- Misalignment may also cause increased noise and vibration.

3. Reduced Lifespan and Unexpected Downtime

- Bearings exposed to dust deteriorate more rapidly, causing premature failure.

- Productivity loss grows when rollers must be replaced frequently or when downtime is required for cleaning.

- In high-throughput environments, this risk directly translates into increased operational costs.

Given these challenges, the need for specialized sealing becomes apparent. Dust-resistant sealing prevents particle intrusion, stabilizes lubrication quality, and helps maintain smooth rotation.

Challenges Presented by Humid or Moist Environments

Humidity introduces a different set of mechanical challenges. Moisture affects metal surfaces, lubrication quality, and internal bearing integrity.

1. Corrosion Risks and Material Degradation

- Humidity encourages oxidation, especially in steel roller bearings.

- Over time, rust forms on inner and outer bearing races.

- Corrosion pits create abrasive surfaces that damage the rolling elements.

- In a Roller Track Conveyor, where continuous movement is expected, such degradation causes noise, sticking, and operational instability.

2. Lubrication Breakdown

- Moisture reacts with oil-based lubricants, causing them to thicken or emulsify.

- When lubrication quality deteriorates, metal-to-metal contact increases, raising friction and wear.

- In humid warehouses or food-processing areas, this effect shortens bearing lifespan significantly.

3. Water Ingress During Washing or Cleaning

- Many facilities clean conveyor lines using washing procedures or high-pressure sprays.

- Water that penetrates unsealed bearings dilutes lubricant and accelerates corrosion.

- For Skate Roller Conveyor designs used in light manufacturing or packaging, repeated exposure may cause rapid bearing failure.

- These problems highlight why proper sealing is crucial to maintain a conveyor system's performance in moisture-prone areas.

How Special Sealing Designs Address Environmental Challenges

Special sealing designs provide mechanical barriers that protect bearings and internal components from contaminants, while also preserving lubrication quality. Different sealing approaches offer varying levels of protection depending on environmental severity.

1. Contact Seals for Dust Protection

- Contact seals physically touch the inner bearing ring, forming a tight barrier.

- They are highly effective in dusty environments with fine powder or particulate matter.

- Although contact seals generate slightly more friction than non-contact versions, the trade-off is justified when dust exposure is high.

- These seals significantly reduce the infiltration of abrasive particles.

2. Non-Contact Seals for Humidity Control

- Non-contact seals provide protection without touching the inner ring, reducing friction and heat.

- They block moisture droplets and prevent water splash entry.

- These seals are especially suitable for conveyors operating in humid warehouses or environments with frequent condensation.

- They help sustain energy efficiency while offering moderate environmental protection.

3. Labyrinth Seals for Harsh Industrial Conditions

- Labyrinth seals use a complex pathway to prevent dust and moisture from entering the bearing housing.

- They offer long-term protection without relying on physical contact.

- This design performs well for both dusty and humid conditions simultaneously.

- They are ideal for areas where cleaning cycles or airborne particulate matter are frequent.

4. Double-Sealed Bearings for Severe Exposure

- Double-sealed bearings combine two layers of protection.

- The inner seal protects lubrication and internal parts.

- The outer seal blocks environmental contaminants before they reach the inner barrier.

- This configuration is common in Light Duty Roller Conveyor assemblies used in outdoor settings or facilities with fluctuating environmental conditions.

Selecting the Right Sealing Approach for Different Conveyor Types

Each type of conveyor—Roller Track, Skate Roller, or Light Duty Roller—has different operational characteristics that influence sealing requirements.

1. Roller Track Conveyor

- Often used for guided material transport where load is distributed evenly.

- Dust and moisture can accumulate between closely aligned rollers.

- Contact seals or labyrinth seals are recommended for extended reliability.

- Systems used in warehousing, manufacturing, or automotive production benefit from additional sealing layers.

2. Skate Roller Conveyor

- Consists of many small rollers mounted on axles, often without powered movement.

- These rollers are highly susceptible to dust intrusion due to exposed edges.

- Lightweight bearings make moisture intrusion damaging, as the lubrication volume is minimal.

- Double-sealed or non-contact sealed bearings are effective solutions.

3. Light Duty Roller Conveyor

- Used for packaging, e-commerce sorting, and manual transport.

- They often operate near cardboard dust, fibers, and humidity from HVAC systems or open doors.

- A combination of dust-resistant sealing and corrosion-resistant materials provides suitable performance.

- Polymeric or stainless-steel components may be selected to further enhance resistance.

Operational Strategies to Enhance Seal Performance

Sealing alone is not enough; operational practices also determine how well the conveyor performs over time.

1. Regular Cleaning Without High-Pressure Sprays

- Avoid excessive water pressure that may bypass seals.

- Use controlled cleaning methods to prevent forced moisture entry.

2. Scheduled Lubrication Maintenance

- Ensure lubricants remain clean and uncontaminated.

- Replace lubricants regularly to prevent emulsification caused by humidity.

3. Environmental Monitoring

- Install humidity sensors or dust-level monitors in sensitive areas.

- Adjust ventilation or implement dust extraction to reduce contamination.

4. Material Selection Enhancements

- Stainless steel or zinc-coated bearings offer better moisture resistance.

- Plastic or polymer rollers reduce corrosion risk in high-humidity zones.

Conclusion

Whether operating a Roller Track Conveyor, Skate Roller Conveyor, or Light Duty Roller Conveyor, it is clear that conveyors exposed to dusty or humid environments need specialized sealing designs to maintain reliability and prolong service life. Dust can infiltrate bearings and wear them prematurely, while moisture can degrade lubrication, cause corrosion, and impair performance. By selecting appropriate sealing systems—contact seals, non-contact seals, labyrinth seals, or double-sealed bearings—operators can significantly reduce downtime, preserve roller efficiency, and maintain stable conveyor flow.

Ultimately, the right sealing strategy ensures that conveyors remain efficient, quiet, and dependable even under challenging environmental conditions, offering long-term operational value and improved safety across industrial applications.

Español

Español Deutsch

Deutsch