How Rubber Hardness and Thickness Shape Conveyor Material Stability

Introduction to Key Roller Types in Conveyor Systems

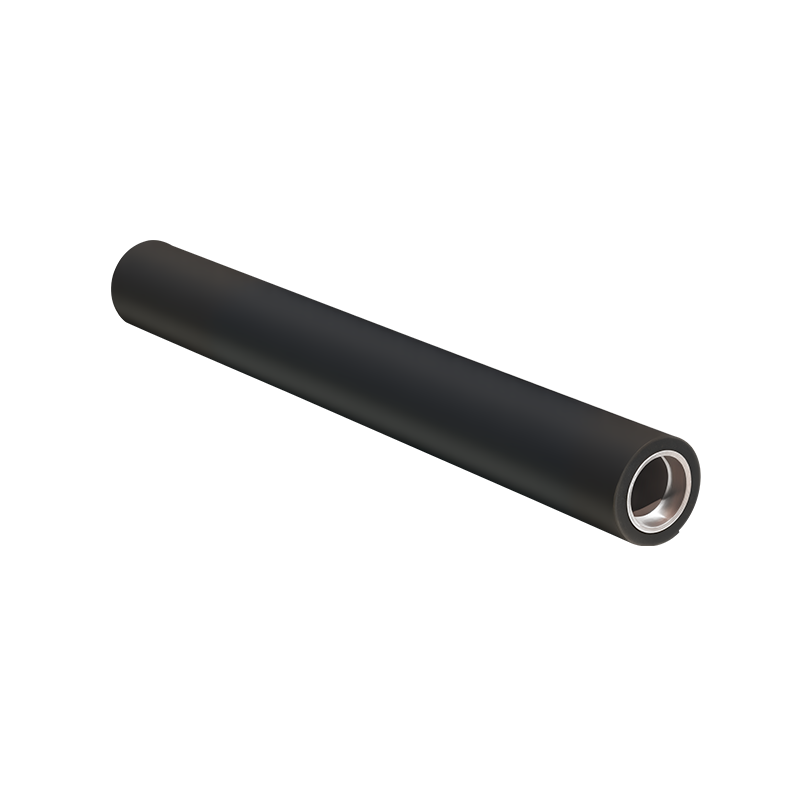

In many industrial conveying environments, components such as Rubber Coated Rollers, Industrial Rubber Rollers, and Rubber Conveyor Rollers are essential for ensuring smooth, reliable, and controlled material transport. These elements come together in the design of Industrial Rubber Coated Conveyor Rollers, a specialized category of rollers whose surface rubber layer plays a decisive role in conveying performance. The hardness and thickness of that rubber coating significantly affect material stability and the friction coefficient—two factors that directly influence the accuracy, safety, and efficiency of a conveyor system.

Hardness determines how much the rubber deforms under load, how well it grips the material surface, and how much vibration it transmits. Thickness affects cushioning, durability, heat dissipation, and surface pressure distribution. Because conveying applications vary widely—from lightweight packaging to harsh mining operations—understanding the mechanical influence of these two rubber characteristics is critical for optimal equipment selection and system design.

How Rubber Hardness Influences Material Stability

Rubber hardness is typically measured using the Shore A scale, and even small differences in hardness can cause noticeable changes in conveying behavior.

1. Hardness and Friction Coefficient

- Softer rubber produces a higher friction coefficient because it conforms more easily to the micro-texture of the transported material.

- This increased surface contact reduces slippage and enhances stability, particularly for lightweight, delicate, or smooth-surface items.

- However, extremely soft rubber can create excessive sticking or rolling resistance, particularly at higher speeds.

- Harder rubber has a lower friction coefficient, which may improve efficiency but can increase the risk of slipping under certain load conditions.

2. Hardness and Vibration Behavior

- Soft rubber absorbs vibration and shock effectively.

- This behavior stabilizes materials when the conveyor encounters misalignments, impacts, or speed fluctuations.

- Such damping is valuable in industries dealing with glass products, electronics, food containers, and other fragile goods.

- Hard rubber transmits more vibration, which can cause materials to bounce, shift, or rotate, especially at high line speeds.

3. Hardness and Load Response

- Hard rubber maintains its shape better under heavy loads.

- This ensures consistent pressure distribution and keeps materials stable even when large or irregular objects are transported.

- In mining, quarrying, or heavy manufacturing, where loads are substantial, harder rubber provides improved structural support.

- Soft rubber under heavy loads can deform excessively, causing uneven contact that destabilizes the material path.

How Rubber Thickness Influences Stability and Friction

While hardness dictates surface behavior, thickness governs how the roller responds to internal stress, impact forces, and long-term wear.

1. Thickness and Contact Dynamics

- Thicker rubber coatings deform more deeply under load, increasing the contact patch and grip.

- This enhances material stability, particularly for items prone to shifting or sliding.

- Excessive thickness, however, may create rolling resistance that reduces system efficiency.

- Thin rubber promotes precise contact but may not provide enough cushioning for sensitive materials.

2. Thickness and Shock Absorption

- A thick rubber coating enhances shock absorption and reduces the transmission of impact forces.

- This is beneficial in systems where materials frequently collide or where frequent start-stop cycles occur.

- Thinner coatings offer limited shock absorption, which may cause instability when transporting fragile or easily displaced materials.

3. Thickness and Wear Life

- Thicker rubber increases roller lifespan by providing more material to resist abrasion, cracking, and environmental degradation.

- It is particularly effective in systems transporting rough, sharp, or abrasive materials such as stone aggregates or scrap metal.

- Thin coatings wear more quickly and may cause inconsistent friction as the rubber layer ages.

Combined Impact of Hardness and Thickness on Conveying Performance

Hardness and thickness interact with each other, and their combined properties determine how the roller behaves in different environments.

1. High Hardness + Thin Thickness

- Provides low deformation and consistent geometry.

- Suitable for precision conveying, such as automated assembly lines or electronic component handling.

- Material may slip if the surface is too smooth or if loads vary significantly.

2. High Hardness + Thick Thickness

- Offers structural strength and robust durability for heavy-duty operations.

- Able to withstand impact from large or abrasive materials.

- Provides a moderate level of grip due to increased thickness but still transmits more vibration than softer combinations.

- Ideal for mining, steel manufacturing, or bulk material transport.

3. Low Hardness + Thin Thickness

- Produces high friction and improved surface sensitivity.

- Suitable for light-duty, precision-oriented operations.

- Minimal cushioning makes it less suitable for irregular or fragile loads.

- Wear occurs faster due to the limited rubber material.

4. Low Hardness + Thick Thickness

- Provides vibration damping and a stable grip.

- Ideal for delicate products requiring gentle handling.

- Excessive deformation may cause instability with heavy loads or high-speed applications.

- May increase conveyor energy consumption due to higher rolling resistance.

Environmental and Operational Considerations

The real-world performance of rubber hardness and thickness is influenced by temperature, humidity, and material characteristics.

1. Temperature Effects

- Soft rubber becomes softer at high temperatures, further increasing friction and deformation.

- Hard rubber becomes harder in cold environments, reducing friction and potentially increasing slippage.

- Thick coatings retain heat longer, which may affect longevity in hot operating conditions.

2. Moisture and Chemical Exposure

- Wet or humid conditions reduce friction on many materials.

- A softer or thicker rubber surface helps compensate by increasing contact area.

- Chemical exposure may require specialized rubber formulations to retain hardness and structural integrity.

3. Material Surface Types

- Smooth materials such as metal sheets benefit from soft rubber for improved traction.

- Rough or textured materials naturally generate more friction, allowing harder rubber to be used without sacrificing stability.

- Lightweight items require more grip, while heavy items demand greater structural support.

Design Considerations for Engineering Applications

For engineers designing conveyor systems using Industrial Rubber Coated Conveyor Rollers, several strategies help achieve ideal performance:

1. Match Rubber Properties to Load Characteristics

- Heavy loads → harder rubber with moderate thickness.

- Fragile items → softer rubber with greater thickness.

2. Implement Hybrid Coating Structures

Multi-layer designs combine soft inner layers for damping with harder outer layers for strength.

3. Prevent Excessive Heat Buildup

Medium-hardness rubber with optimized thickness reduces frictional heat.

4. Use Surface Patterning

Grooves or textures increase grip without drastically altering hardness.

The hardness and thickness of the rubber coating on Industrial Rubber Coated Conveyor Rollers play a central role in determining how stably materials move and how effectively the roller grips different surfaces. Hardness influences friction coefficient, deformation, load support, and vibration transmission, while thickness shapes shock absorption, durability, and contact quality. When combined strategically, these two parameters allow conveyor systems to achieve precise performance tailored to their specific industrial requirements. By selecting the right balance of hardness and thickness, engineers can optimize conveying efficiency, protect fragile materials, and ensure long-term reliability across diverse working environments.

Español

Español Deutsch

Deutsch