Advantages and Disadvantages of the Aluminum Guide Roller

Comparing Different Roller Materials

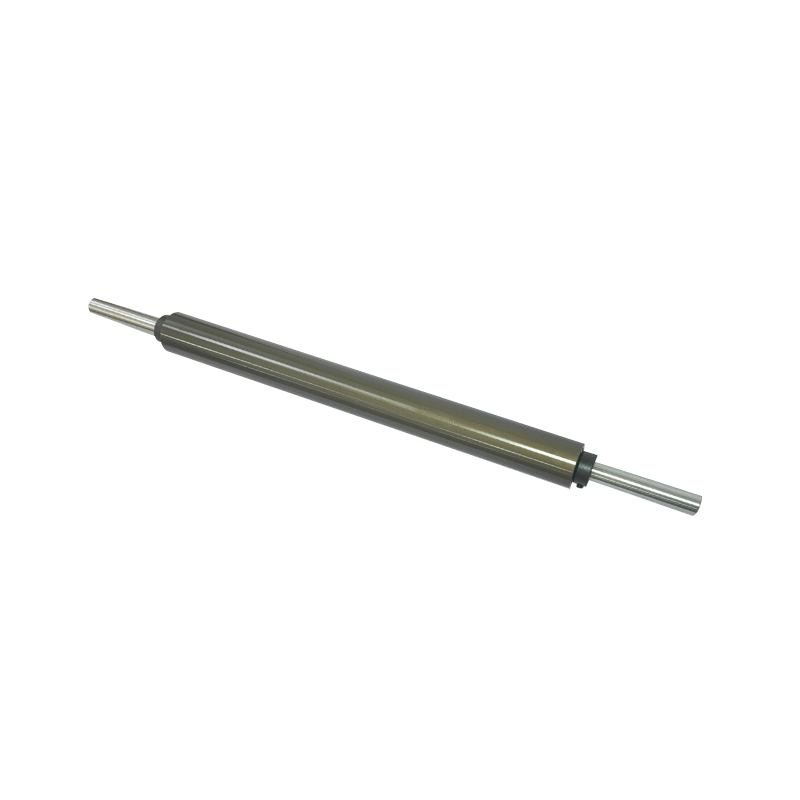

Aluminum Guide Roller is widely used in industrial and mechanical systems for guiding, supporting, and transferring loads along tracks or rails. When selecting a roller, engineers often compare aluminum with steel or plastic alternatives. Understanding the advantages and disadvantages of aluminum rollers helps in choosing the suitable solution for specific applications, balancing durability, weight, cost, and operational requirements.

Lightweight and Ease of Installation

One of the main advantages of the Aluminum Guide Roller is its lightweight nature. Compared to steel rollers, aluminum significantly reduces the overall system weight, which simplifies installation and reduces structural load on supporting frames. Lighter rollers also decrease inertia, allowing for smoother acceleration and deceleration in conveyor systems. While plastic rollers are also lightweight, aluminum provides higher strength-to-weight ratios, making it suitable for medium to heavy-duty applications where plastic may not be strong enough.

Corrosion Resistance

Aluminum naturally forms an oxide layer on its surface, providing inherent corrosion resistance. This makes the Aluminum Guide Roller particularly suitable for outdoor, humid, or mildly corrosive environments without requiring additional coatings. Steel rollers, unless treated or stainless, are more prone to rust, which can compromise performance and increase maintenance costs. Plastic rollers resist corrosion as well, but may degrade under UV exposure or chemical contact. Aluminum thus offers a balanced solution with both strength and moderate environmental resilience.

Strength and Load-Bearing Capacity

Aluminum rollers provide good structural strength for a variety of applications. While not as strong as steel, aluminum is adequate for many medium-load scenarios and offers better resistance to deformation compared to plastic rollers. Steel rollers excel in heavy-duty applications due to their high tensile strength, but they are heavier and more expensive. Plastic rollers are generally limited to light-duty loads and may deform under prolonged stress, whereas an Aluminum Guide Roller can maintain dimensional stability under moderate pressures, making it versatile for industrial use.

Wear Resistance and Maintenance

The wear resistance of the Aluminum Guide Roller depends on surface treatments such as anodizing or hard coating. These treatments enhance hardness and reduce friction, improving durability. Steel rollers naturally have higher wear resistance but require lubrication to prevent rust. Plastic rollers have lower wear resistance and may experience surface abrasion over time. Aluminum rollers offer a balanced combination of reasonable wear resistance and low maintenance, particularly when combined with proper bearings and lubrication.

Cost Considerations

Aluminum Guide Roller typically costs more than plastic rollers but less than steel alternatives. The initial investment is balanced by its advantages in weight reduction, corrosion resistance, and moderate strength. Steel rollers may have higher durability but require more structural support and maintenance, potentially increasing total cost. Plastic rollers are cheap but limited in load capacity and environmental resistance. For many industrial applications, aluminum provides a suitable balance between performance and cost efficiency.

Limitations and Considerations

Despite its advantages, the Aluminum Guide Roller is not ideal for extremely high-load or high-impact applications where steel is required. Additionally, aluminum can be prone to surface scratching and may deform under excessive pressure without proper support. For environments with strong chemical exposure, aluminum may also react with certain substances. Careful selection of roller diameter, wall thickness, and surface treatment can mitigate these limitations and improve performance.

Balanced Choice for Medium-Duty Applications

Aluminum Guide Roller offers lightweight construction, corrosion resistance, reasonable strength, and moderate wear resistance, making it a good choice for medium-duty applications. Compared to steel rollers, it reduces weight and installation effort, while offering better environmental resistance than many plastic alternatives. However, for extremely heavy loads or highly corrosive conditions, steel or specialized plastics may be preferred. Understanding these trade-offs ensures suitable roller selection and system performance in industrial, mechanical, or conveyor applications.

Español

Español Deutsch

Deutsch