Environmental Temperature Effects on Rubber-Coated Conveyor Roller Performance

Temperature Sensitivity of Rubber-Based Conveyor Components

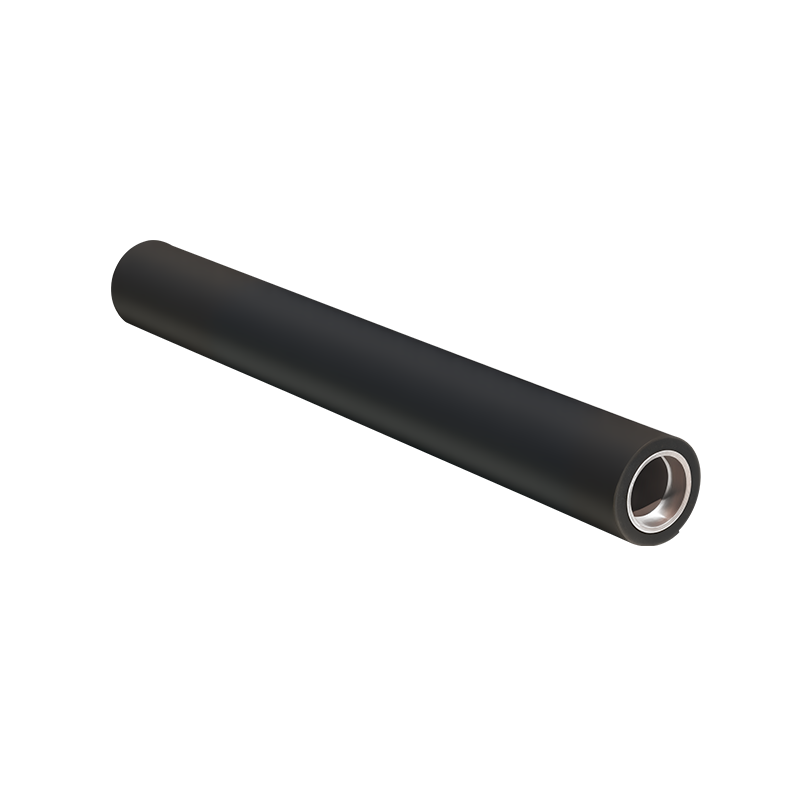

In industrial conveying systems, Rubber Coated Conveyor Rollers, Rubber Track Rollers, and Rubber Feed Rollers are widely used for applications involving traction, controlled feeding, vibration absorption, and stable material transport. These rollers depend heavily on the mechanical behavior of rubber, which is highly sensitive to environmental temperature. Whether the system is placed in furnace-adjacent zones, cold-storage environments, outdoor mining sites, or variable-climate production lines, temperature fluctuations directly influence roller elasticity, hardness, surface energy, friction behavior, and long-term durability. Before exploring the deeper engineering mechanisms, it is important to recognize that rubber undergoes physical transitions such as softening, hardening, glass transition, and thermal aging at different temperatures. These transitions guide how the rollers perform and how the conveyor system must be adjusted to maintain reliable operation.

The following analysis explores in detail how high-temperature and low-temperature environments affect the mechanical behavior, structural stability, friction characteristics, and service life of rubber-coated conveyor rollers used for track-feed or material-positioning applications.

High-Temperature Effects on Material Properties

1. Rubber Softening and Loss of Hardness

- When exposed to high temperatures, rubber tends to soften.

- The molecular chains in the elastomer become more flexible, reducing surface hardness.

- This softness can cause excessive deformation under load, affecting roller alignment and creating uneven pressure distribution across the conveyor belt.

- Softened rubber loses its ability to maintain dimensional accuracy in precision feed applications, potentially causing slippage.

- If temperatures rise beyond the rated capacity of the rubber compound, the softening becomes irreversible due to cross-link breakdown.

2. Increased Surface Stickiness and Contamination Risks

- High temperatures increase the surface tackiness of rubber.

- Sticky surfaces may attract dust, oil, or particles from conveyed materials.

- Contaminated roller surfaces disrupt traction consistency and cause jerking movements in feed conveyors.

- Sticky rubber also increases belt wear, particularly when operating at high speeds.

- This change in surface behavior creates maintenance challenges that do not exist in moderate-temperature environments.

3. Accelerated Thermal Aging and Cracking

- Thermal aging is one of the significant risks in high-temperature operation.

- Elevated heat accelerates oxidation, altering rubber’s chemical structure.

- Over time, the surface may develop micro-cracks, causing brittleness.

- Aging weakens the roller’s ability to provide stable friction and increases the likelihood of catastrophic failure.

- Thermal aging becomes more severe in environments involving both heat and mechanical stress, such as continuous track-feed systems.

High-Temperature Effects on System Performance

1. Altered Friction Coefficient

- Friction between the conveyor belt and roller changes as the temperature increases.

- Softer rubber generates inconsistent friction, causing variable speed transmission.

- Excessively high friction may overload drive motors or create belt heating.

- Insufficient friction may cause misfeeds or irregular material movement.

- Maintaining a predictable friction coefficient is essential for feeding accuracy.

2. Reduced Load-Bearing Capacity

- Load capacity is influenced by rubber elasticity.

- At high temperatures, rollers deform more under weight, reducing their effective load rating.

- Deformation can cause belt misalignment or uneven feed patterns.

- In heavy-duty conveyors, deformation may also cause roller bending or bearing overload.

- Engineers must re-evaluate load allowances when operating in high-temperature zones.

3. Lubrication Difficulties in Bearings

- Adjacent bearings experience thermal expansion.

- High heat reduces lubricant viscosity, weakening lubricating performance.

- Bearing seals may degrade, allowing contaminants to enter.

- Reduced lubrication accelerates wear and may cause bearing seizure.

- Thus, the performance of rubber-coated rollers is not isolated but interconnected with the mechanical components around them.

Low-Temperature Effects on Material Properties

1. Rubber Hardening and Increased Brittleness

- Low temperatures cause rubber to harden significantly.

- Molecular mobility decreases, reducing elasticity.

- Hard rubber surfaces lose their ability to deform under load, affecting contact quality with the conveyor belt.

- In cold, rubber may approach its glass-transition temperature, becoming brittle enough to crack.

- These brittle transitions can severely reduce roller lifespan in environments like refrigerated warehouses or outdoor winter operations.

2. Red uced Traction Capability

- As rubber hardens, its grip diminishes.

- Lower friction increases slippage between the roller and the belt.

- The loss of traction affects the accuracy of feed conveyors that rely on a consistent gripping force.

- Slippage increases belt wear and can disrupt synchronization in multi-roller systems.

- Low traction is particularly problematic for incline conveyors and applications requiring precise movement.

3. Increased Risk of Surface Abrasions

- Hard rubber behaves more like a plastic surface.

- It becomes less resistant to abrasive particles such as sand, ice crystals, or dust.

- Repeated abrasion causes surface roughness that introduces unwanted vibration.

- Surface pitting reduces long-term stability and may require premature roller replacement.

- Cold environments, therefore, increase maintenance frequency.

Low-Temperature Effects on System Performance

1. Decreased Shock-Absorption Ability

- The cushioning effect of rubber diminishes in cold conditions.

- Hard surfaces transmit more vibration through the conveyor structure.

- Reduced shock absorption increases noise and accelerates joint fatigue within the system.

- Conveyed materials that require gentle handling may be damaged.

- Track-feed systems transporting fragile items are particularly vulnerable.

2. Higher Torque Requirements

- Low-temperature hardening increases rolling resistance.

- Motors must apply additional torque to overcome resistance.

- Power consumption rises, and mechanical stress increases.

- In severe cold, start-up torque may exceed motor capacity, causing operational delays.

- Engineers may need to select stronger motors for cold-region installations.

3. Lubrication Issues in Bearings

- Cold temperatures affect bearing lubrication opposite to high temperatures.

- Lubricants thicken and lose flowability.

- Bearings may fail to rotate smoothly, causing uneven roller rotation.

- Cold-induced metal contraction can increase preload on bearings.

- These issues introduce variability into feed accuracy and belt alignment.

- Environmental Cycles: Repeated Heating and Cooling

In environments with fluctuating temperatures, such as outdoor mining or agricultural settings, rubber rollers endure repeated thermal cycling.

- These cycles accelerate fatigue within the rubber compound.

- Cracking occurs more readily when rubber repeatedly expands and contracts.

- Variations in elasticity cause inconsistent performance, affecting the stability of the entire conveyor line.

- Thermal cycling is often more damaging than constant high or low temperatures.

Engineering Solutions for Temperatures

1. Selecting Temperature-Resistant Rubber Compounds

- Different applications may require specialized rubber formulations:

- Silicone and EPDM resist high temperatures.

- NBR and natural rubber maintain flexibility in moderate cold.

- Polyurethane outperforms rubber in certain high-abrasion cold environments.

- Choosing the right material is the one step toward reliable operation.

2. Adding Heat Shields or Insulation

- For high-temperature exposure:

- Heat shields deflect radiant heat.

- Insulated housings protect the roller surface from thermal spikes.

- Cooling airflow can be added in furnace-adjacent conveyors.

3. Adding Low-Temperature Flexibility Treatments

- For cold environments:

- Heating bands can be wrapped around rollers.

- Temperature-stable lubricants reduce bearing friction.

- Pre-operation warm-up cycles improve elasticity.

- These modifications maintain performance during seasonal climate changes.

Designing for Stable Performance Across Temperatures

Rubber-coated track-feed conveyor rollers are indispensable to modern conveying systems, but their performance depends heavily on the surrounding temperature environment. High temperatures soften rubber, increase adhesion, and accelerate aging, while low temperatures harden the material, reduce traction, and increase brittleness. Both influence friction coefficients, load-bearing capacity, shock absorption, and roller longevity. By understanding these mechanisms and adopting temperature-appropriate materials and engineering adjustments, industries can ensure stable, safe, and efficient operation in environments ranging from refrigerated processing to furnace-adjacent manufacturing lines.

Español

Español Deutsch

Deutsch