With over 20 years of expertise in precision machining, Ruian Baixiao Machinery Co., Ltd. has developed a fully integrated operation encompassing R&D, manufacturing, sales, and after-sales support.

We specialize in designing and producing aluminum guide rollers, air expansion shafts, steel and stainless-steel rollers, slip shafts, slip sleeves, and magnetic powder clutches/brakes.

Backed by comprehensive specifications and advanced production technology, Baixiao delivers reliable mechanical components for printing, packaging, plastics, paper, and a wide range of coil-processing industries. Our products are especially trusted in color printing and flexible packaging machinery, where precision, stability, and long-term durability are critical.

Printing & Packaging Roller Manufacturer

High-Precision Conveyor, Extrusion & Idle Rollers for the Web Processing Industry.

Smooth Handling | Heavy-Duty Performance | Long-Lasting Durability

MOQ 5 pcs

Widely used in slitting, film, printing, flexo and packaging machines.

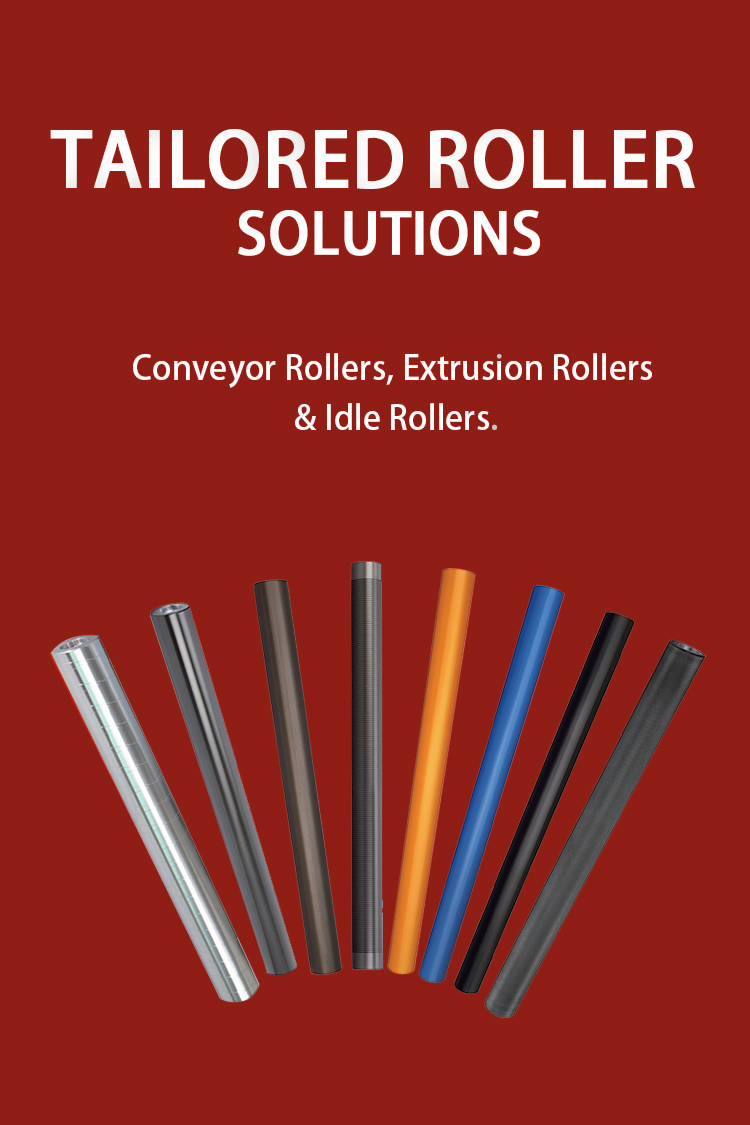

Tailored Roller Solutions

Our Products: Conveyor Rollers, Extrusion Rollers & Idle Rollers.

Conveyor Rollers: Suitable for slitting machines, film machines, printing, flexographic printing, and packaging machines.

Extrusion Rollers: Suitable for rubber, plastics, textiles, laminating, and pressing systems.

Idle Rollers: Used for belt stabilization and material flow support.

Aluminum Rollers - High Precision & Lightweight

Concentricity up to 0.02 mm, balancing accuracy within 2 g. Max 300 mm diameter, 5,000 mm length. Multiple surface options: sandblasted, textured, grooved, center-slotted, cross-patterned, and hard anodized.

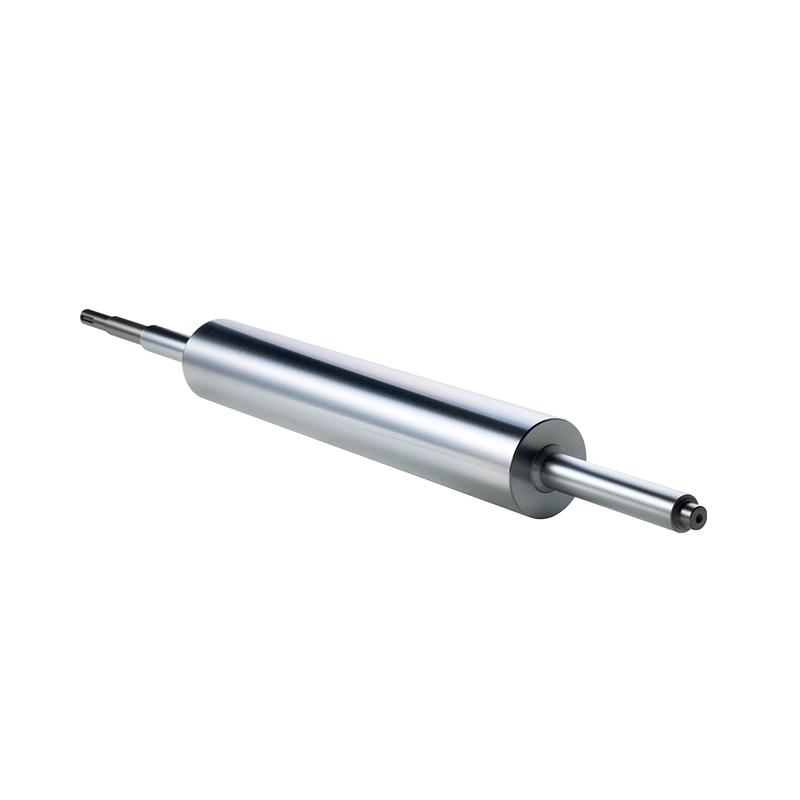

Steel Rollers - High Load & Long Life

Precision-machined from premium steel for stable performance at high load and high speed. Surface treatments include hard chrome plating, polishing, and knurling.

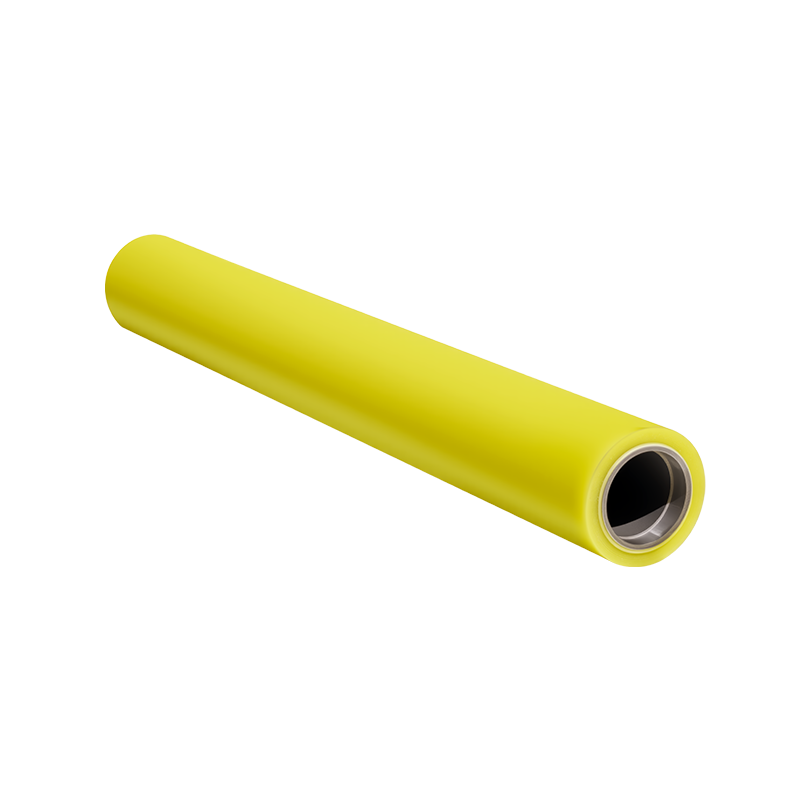

Rubber Rollers - Strong Grip & Anti-Slip

Available in neoprene, nitrile, polyurethane, silicone, CSM, and EPDM. High friction for reliable conveying. Length customizable up to 3,000 mm.

Carbon Fiber Rollers - Ultra-Light & Vibration Damping

Reduces mechanical load on shafts and equipment. Excellent durability, corrosion resistance, and vibration absorption.

20+ Years of Manufacturing Experience丨MOQ 5 pcs丨100+ Models

Custom Sizes · Materials · Surface Treatments

About Us

-

16000m²

Factory area

-

200+

Serving Staff

-

20+

Industry Experience

-

35+

Export Region

Production Capacity & Scale

● Production Capacity: With over 10,000 tons of raw materials in reserve, we maintain a stable daily output of 5,000+ units, ensuring reliable fulfillment of customer orders.

● Large-Scale Single-Piece Capability: Our product range supports guide rollers with diameters up to 300 mm and lengths up to 5,000 mm, meeting the needs of heavy-duty and wide-format applications.

● Customization Speed: We provide rapid customization services with delivery in as fast as 10 days, helping customers minimize downtime and keep production running smoothly.

● Factory Scale: Our modern manufacturing facility spans 20,000 m², enabling efficient, organized, and high-volume production.

● Extensive Product Range: Offering 100+ specifications and models, we supply aluminum guide rollers, steel rollers, air shafts, rubber rollers, and a comprehensive selection of related components.

Exhibition & Factory

Honor

-

Q: Can you make custom products?

Yes, we mainly make custom products. We develop and produce products based on drawings or samples provided by customers.

-

Q: What is your company's production capacity?

A: We have over 10 assembly lines and over 60 production lathes, producing an average of 5,000 products daily.

-

Q: How does your company ensure product quality?

A: We adhere to strict ISO-standardized production processes, performing 12 rigorous quality inspection steps from raw material selection to finished product testing. This ensures the precision and accuracy of products like aluminum guide rollers and air shafts. We guarantee full factory inspection and rigorous control of key performance indicators.

INQUIRY NOW

Contact Us And Get A Quote Priority To Learn About Our New Prod!